Effects of Sand/Fly Ash and the Water/Solid Ratio on the Mechanical Properties of Engineered Geopolymer Composite and Mix Design Optimization

Author: Nasir Shafiq - April 2020

Abstract

This paper presents the results of an experimental study that investigated the effects of two parameters: sand/fly ash (S/FA) ratio and water to geopolymer-solid (W/GS) ratio on the engineered geopolymer composite. The trial mix designs were optimized using the response surface method. These parameters influence the properties of the fresh and hardened geopolymer matrix, such as slump flow, compressive strength, flexural strength, elastic modulus, flexural toughness, ductility index and drying shrinkage. The optimizing process was conducted by developing statistical models using the response surface methodology (RSM) technique. The developed models were statistically validated and could be used to determine the desired response of engineered geopolymer composite (EGC) with a significance level of more than 95%. In this study, the optimized values of the S/FA ratio and W/GS ratio were obtained as 0.341701 and 0.225184, respectively. To validate the optimized S/FA ratio and W/GS ratio, an experimental study was performed, and a difference of less than 5% was found between predicted and experimental results.

Methodology

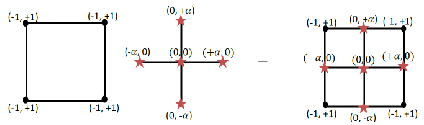

The trial and error method has conventionally been practiced to find out the influence on the responses by changing the value of one variable at a time. This process is time-consuming, especially for multivariable systems. Therefore, it is needed to utilize a robust technique for solving multiobjective optimization problems. The response surface method (RSM) is a robust approach for optimizing complex problems through the development of statistical interaction between factors (independent variables) and responses (dependent variables). The process of optimization through RSM is initiated with the systematic designing of experiments and through the collections of responses by performing experimental programs. Finally, statistical models are developed for the prediction of each response, and optimization is performed for the desired targets. The most practically adopted method for experimental design, statistical modeling, and optimization is the central composite design (CCD) of RSM. The process of selection of data points through CCD using RSM is illustrated in Figure 2. The experiments are designed so that the space of independent variables must include corner points (+1 and -1), a center point, and extreme points ( + and -). Quadratic models that are used to estimate each response are developed using the 2nd-degree polynomial Equation

Impact & Benefits

Environmental Sustainability and Green Alternatives: The environmental concerns associated with traditional Portland cement production, which contributes to approximately 10% of global CO2 emissions.

Superior Mechanical Properties of Fly Ash-Based Geopolymer Concrete:The superior compressive strength of geopolymer binders creates opportunities for applications in the construction industry, offering a potential alternative to traditional concrete in specific use cases.

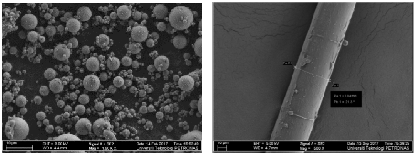

Intrinsic Reinforcement with Short and Oriented Fibers: The incorporation of fibers, particularly PVA fibers, enhances tensile strength, ductility index, and post-crack performance. This intrinsic reinforcement improves the overall performance and durability of geopolymer concrete.

Market Potential

Efficiency in Geopolymer Concrete (EGC) Production:: The study focuses on optimizing dosages of water/geopolymer solids (W/GP) and sand/fly ash (S/FA) in Engineered Geopolymer Composite (EGC) using response surface methodology (RSM).

Quality Control and Predictive Modeling:The use of response surface diagrams and contour diagrams, along with ANOVA equations, indicates a focus on quality control and predictive modeling in the production of EGC.