The effects of temperature, residence time and particle size on a charcoal produced from coconut shell

Author: Shaharin Anwar Sulaiman - June 2020

Abstract

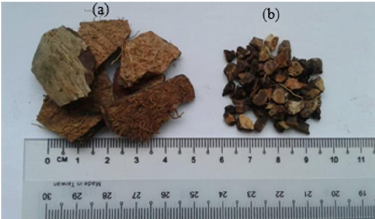

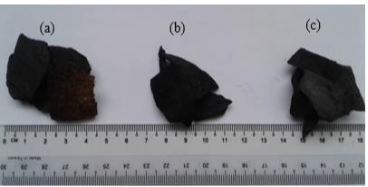

Coconut shell charcoal is an important product obtained from coconut shells, which are widely used as domestic and industrial fuel. Wastes of coconut residues (shells, husks and coir) from processing of coconut milk and oil industries are widely generated everywhere all over the world. They have the potential of use as a fuel in renewable energy for different applications. In this study, the production of charcoal from coconut shell through the process of pyrolysis was conducted to determine the influence of particle size, temperature and residence time on the charcoal weight loss. Pyrolysis is a thermochemical conversion method which converts biomass into more valuable products in form of solid (charcoal, bio-char and activated carbon), liquid (oil) and gas in the absence of oxygen. The process was carried out under various process conditions of temperature (300 Celcius, 400 Celcius, and 500 Celcius), residence time (15 minutes, 30 minutes, and 60 minutes), and particle size (5.0 mm and 25.0 mm). It was found that for both the temperature and the residence time, the weight loss from the coconut shell increase linearly with increase in temperature and residence time. The particle size has influence in percentage weight loss. The resulting charcoal obtained can be utilized as an alternative energy resource for different applications.

Methodology

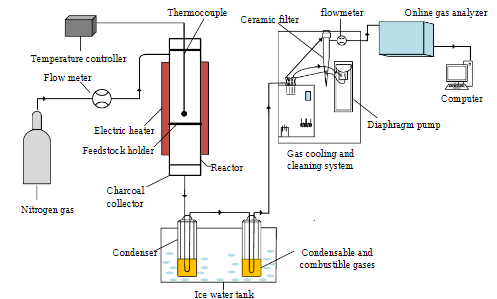

As the feedstock (100 g) was loaded to the pyrolysis reactor, the temperature was raised from 100 Celcius to desired temperature and residence time. Nitrogen gas (flow rate of 20 mL/minute) was used to obtain the inert condition and sweep away the volatile vapors. While the breakdown of the coconut shells structure continues at a specific temperature, the vapor gives off as condensable vapors and the non-condensable gases, which include carbon monoxide, hydrogen, methane, and carbon dioxide gas. The heating process was stopped at the desired temperature and residence time. The charcoal was collected at and placed in a desiccator to avoid moisture gain or loss. The gas was condensed by a condenser with an ice cooling system to collect the liquid that contain bio-oil and water bio-oil.

Impact & Benefits

The increase in residence time during the pyrolysis process results in a higher percentage of weight loss for coconut shells charcoal. This suggests improved efficiency in the pyrolysis process, allowing for more complete conversion of the feedstock into charcoal.

A shorter residence time (15 minutes) leads to incomplete pyrolysis, with only 48.88% weight reduction. This indicates that insufficient time for the pyrolysis process can result in incomplete conversion of the feedstock.

By understanding the impact of residence time on weight loss, the study provides valuable insights for optimizing the pyrolysis process. This information can guide adjustments in residence time to achieve desired outcomes in terms of weight loss and charcoal quality.

The text emphasizes that fine particles exhibit a uniform heating rate due to negligible heat transfer resistance. This leads to more uniform drying and primary pyrolysis throughout the particles, which can be advantageous for achieving consistent and desirable pyrolysis outcomes.

Market Potential

Effect of Pyrolysis Conditions on Weight Loss: Higher residence time and temperature during the pyrolysis process lead to increased weight loss from coconut shells. This implies that extending the duration of the process and elevating the temperature result in more effective pyrolysis and greater weight reduction.

Implications for Charcoal Production: The obtained results offer insights into the optimization of conditions for charcoal production. Understanding how these conditions interact is crucial for achieving efficient and effective charcoal production processes.

Relevance for Reactor System Design: The importance of considering optimal conditions in the design of reactor systems for charcoal production. This knowledge can contribute to designing systems that maximize production efficiency and overall process performance.

Environmental Health Benefits:The conversion of coconut shells into charcoal through pyrolysis is portrayed as a positive step towards minimizing environmental health issues. This process may offer a sustainable and eco-friendly alternative to traditional waste disposal methods.