Recovery of gas waste from the petroleum industry: a review

Author: A Rashid A Aziz - November 2021

Abstract

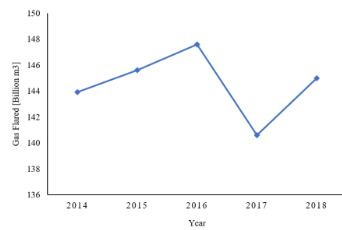

Globally, 150-170 billion cubic metres of gas are being flared annually from petroleum refineries, petrochemical industries and from landfills. In this paper, we critically review the flaring technology, the impact of flare gas on the environment, and recovery options. We also discuss flare gas challenges such as technical, structural, economic, and regulatory challenges. We found that ground flaring is preferred whenever the facility is situated in a highly populated area or close to an aviation zone. Gas flaring produces major pollutants including benzene, benzopyrene and toluene. The recovery of this gas should be intensified to minimise impacts.

Methodology

This paper is using qualitative method in reviewing the paper to assess the current status quo of flaring reduction initiatives and the challenges that are still faced. The research questions listed below necessitate answers which are provided by the present review. What is the prospect of flaring technologies? How can we make the best out of the current practice? How can we contain the slip effect of gas and improve combustion efficiency?

Impact & Benefits

Impact on human health: Sulphide hydrogen: affects the eye and nose and results in headaches and insomnia. Sulphur dioxide: airway obstruction and severe respiratory system complications. Nitrogen oxides: increase in allergens for asthmatics and increased risk of lung irritations and dysfunctions. Carbon monoxide: potential long-term health effects in addition to headaches, nausea, and weakness. NMVOC (non-methane volatile organic compounds):- impacts the respiratory and cardiovascular systems. Aromatics (e.g., benzene, toluene, xylene): poisonous and carcinogenic, influence the nerve system, cause blood abnormality. Black carbon: accumulation of dust in the pulmonary system and pneumoconiosis.

Thermal and heat radiation impact: Gas flaring results in an increase in surface temperature. Julius (2011) reported a surface temperature increase of 9.1 Celcius above the mean normal daily temperature. The author suggested that residential buildings should be at least 210 m away from the flare stack. Furthermore, flares contribute significantly to heat radiation. However, there are further studies needed to explore the effect of flares on thermal and heat radiation (Ite and Ibok, 2013). It is reported that gas flares release around 45.8 billion kW of heat into the atmosphere in the Niger Delta daily. As a result, it has raised temperatures and rendered large areas of Niger Delta (Ismail and Umukoro, 2012)

Photochemical impact:The conversion of nitric oxide to nitrogen dioxide results in the photochemical formation of O3. Short-lived radical sources such as formaldehyde and nitrous acid increase ozone productivity. It is reported that primary formaldehyde produced in flares may increase peak ozone by ~30 ppb (Webster et al., 2007).

Economic impact:Gas flaring is a colossal waste of energy, e.g., in 2018, in the Permian Basin, an estimated $1 million of natural gas was flared off each day which could have been utilised. North Dakota's 24 Bakken Shale flared 20% of the daily drilled natural gas, which was enough to heat all the state's houses for one month, ten times over (International, 2019).

Agricultural impact:Gas flares adversely affect the microbial populations, organic matter and total nitrogen, humid (topsoil) formation, nutrient availability and soil fertility-subsequently these impact crops due to modification of the microclimate in the region (Ite and Ibok, 2013). Furthermore, the toxic contaminant mixtures from gas flaring may affect aquatic organisms by altering their phylogenetic position and reducing relative sensitivity. Isichei and Sanford (1976) reported increased air, soil and leaf temperatures and reduced relative air humidity within 110 m from the flare sites. Similar results were reported by Odjugo et al. (2009).

Market Potential

The majority of the studies on flare gas recovery technologies are comparative evaluations using process modelling of different techniques focussed on their economic and technical impact. While such modelling studies are useful, it is believed that the models should be validated through field data, such as real-time variation of gas quantity and gas composition. Among the flare gas recovery technologies, gas to power (grid and local) is economically viable in most cases. However, gas to power is only suitable when it is implemented with a lean fuelling strategy to minimise the concentration of emissions. Besides, other performance improvements, such as combined heat and power and the combined cycle gas turbine, will make this technology economically and environmentally competitive. The current search for new scalable and low energy-intensive gas to liquid conversion technology may take the lead. In oil fields with tight oil formations, a combination of techniques is found to be more effective over single technique solutions.