Experimental Correlation of the Role of Synthesized Biochar on Thermal, Morphological , and Crystalline Properties of Coagulation Processed Poly(1,4-phenylene sulfide) Nanocomposites

Author: Faiz Ahmad - April 2023

Zaib Un Nisa, Lee Kean Chuan, Beh Hoe Guan,Saba Ayub

Abstract

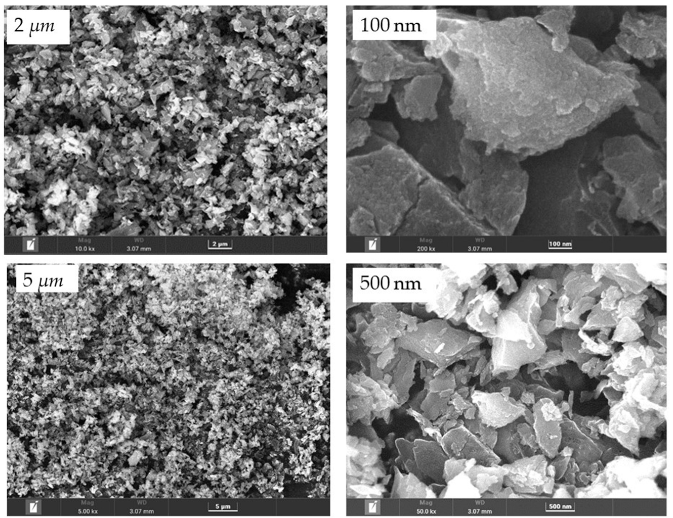

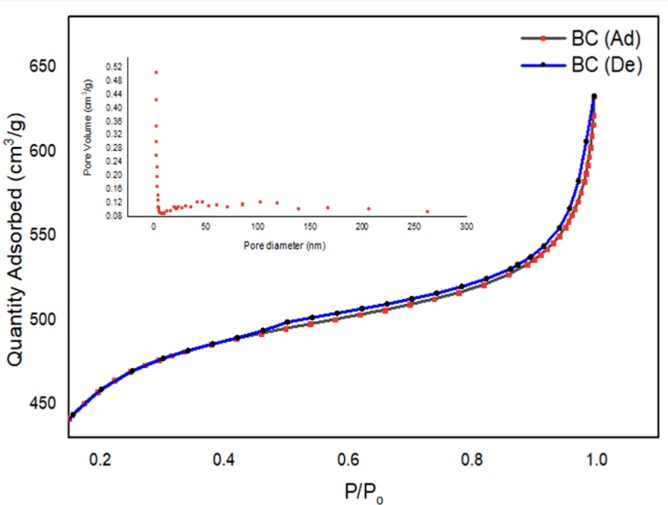

This work aimed to study the thermal and crystalline properties of poly (1,4-phenylene sulfide)@carbon char nanocomposites. Coagulation-processed nanocomposites of polyphenylene sulfide were prepared using the synthesized mesoporous nanocarbon of coconut shells as reinforcement. The mesoporous reinforcement was synthesized using a facile carbonization method. The investigation of the properties of nanocarbon was completed using SAP, XRD, and FESEM analysis. The research was further propagated via the synthesis of nanocomposites through the addition of characterized nanofiller into poly (1,4-phenylene sulfide) at five different combinations. The coagulation method was utilized for the nanocomposite formation. The obtained nanocomposite was analyzed using FTIR, TGA, DSC, and FESEM analysis. The BET surface area and average pore volume of the bio-carbon prepared from coconut shell residue were calculated to be 1517 m2/g and 2.51 nm, respectively. The addition of nanocarbon to poly (1,4-phenylene sulfide) led to an increase in thermal stability and crystallinity up to 6% loading of the filler. The lowest glass transition temperature was achieved at 6% doping of the filler into the polymer matrix. It was established that the thermal, morphological, and crystalline properties were tailored by synthesizing their nanocomposites with the mesoporous bio-nanocarbon obtained from coconut shells. There is a decline in the glass transition temperature from 126°Cto 117°Cusing 6% filler. The measured crystallinity was decreased continuously, with the mixing of the filler exhibiting the incorporation of flexibility in the polymer. So, the loading of the filler into poly (1,4-phenylene sulfide) can be optimized to enhance its thermoplastic properties for surface applications.

Methodology

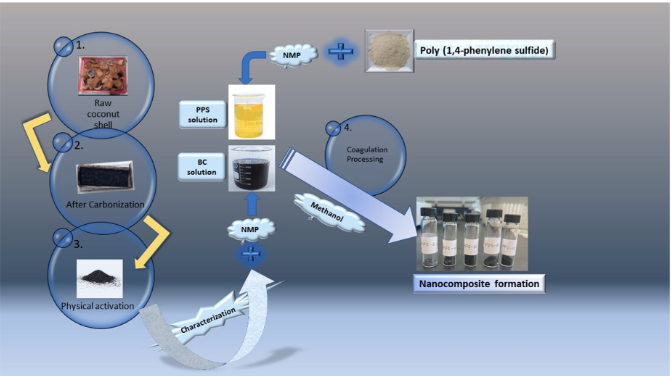

PPS powder (average Mn = 10,000 g mol-1, density = 1.36 g/mL at 25°C) was supplied by Sigma-Aldrich (St. Louis, Missouri, USA); an NMP reagent grade was purchased from Supelco (Darmstadt, Germany, b.p. = 202°C). Methanol was obtained from Friendemann Schmidt (sdn bhd, Kuala Lumpur, Malaysia, b.p. = 64.9°C) and used as received. The mesoporous biochar (BC) was synthesized from the coconut shell and characterized in the laboratory using the following carbonization technique. The schematic diagram for the workflow is presented in Figure 1.

Impact & Benefits

Thermal Stability: Carbon fillers significantly improve the thermal stability of polymer composites, making them suitable for high-temperature applications.

Affordable Raw Materials: Using biochar derived from agricultural waste provides a cost-effective alternative to traditional carbon fillers.

Environmental Benefits: Utilizing agricultural waste to produce biochar helps in waste management and reduces the environmental impact.

Crystallinity and Flexibility:Incorporating biochar improves the crystallinity and flexibility of the polymer, enhancing its overall performance.

Durability: The enhanced properties result in composites that are more durable and have a longer lifespan.

Reduced Material Costs:The low cost of biochar as a filler material reduces the overall cost of producing high-performance polymer composites.

Findings/Figures and Research Data

There are distinguishing features, such as interior voids and the continuous saturation of BC nanoparticles into the polymeric matrix. No evidence of the aggregation of BC was perceived, indicating a supportive role of the coagulation method in the wetting of the PPS resin with filler. Carbon-based fillers have been reported to increase the porosity of polymer nanocomposites due to higher surface areas [53]. The detailed morphological images, obtained using EDS, are provided as BSE (backscattered electron) images in Figure 15. These in-depth images also correlate, in surface morphology, with FESEM images. The results of the weight fraction of carbon in the prepared nanocomposites are provided in Figure 16. This also indicated an increase in carbon content with the addition of BC.

Market Potential

Polymer Composites: There is increasing demand for advanced polymer composites in various industries, including automotive, aerospace, electronics, and construction. These composites offer enhanced properties such as improved thermal stability, mechanical strength, and corrosion resistance.

Biochar's Advantages: Biochar, particularly from coconut shells, offers advantages such as high strength, low density, and excellent abrasion resistance, making it a cost-effective and efficient filler for polymers.

Automotive and Aerospace:The demand for lightweight, durable, and heat-resistant materials in these sectors is a significant driver for the adoption of biochar-based composites.

Electronics: Improved conductive and thermal properties make these composites suitable for electronic components, including fuel cells and batteries.

Construction: Enhanced mechanical properties and sustainability aspects appeal to the construction industry for use in building materials and coatings.