Flow induced fiber orientation in short carbon fiber reinforced copper matrix composites

Author: Faiz Ahmad - December 2022

Saad Ali, Muhammad Irfan Shiraz, Khurshid Malik, Muhammad Rafi Raza , Iqbal Rasool Memon

Abstract

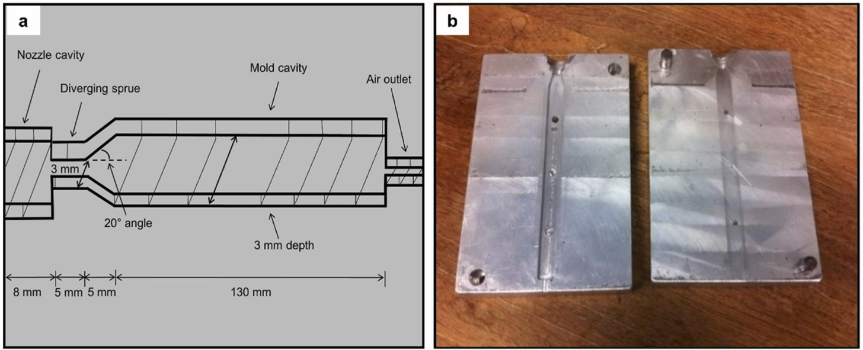

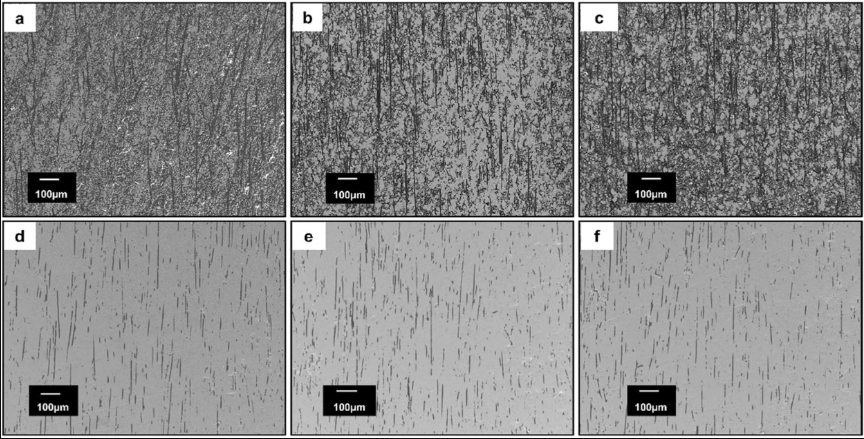

This study investigated the effect of a distinctive design of mold to align short carbon fiber in copper matrix composite produced via metal injection molding. The mold was designed to improve the fiber orientation during flow in the core region of test samples. The composite feedstocks comprising polymeric binder and Cu powder reinforced with 0, 5 and 10 vol. % carbon fiber, prepared in Z-blade mixer, were injection molded to fabricate green samples. Green samples were debound to remove the binder and sintered in sintering furnace at 1050 ° in Argon atmosphere. Dispersion of carbon fibers was examined in composite feedstocks and TGA was used to determine the degradation temperature of binder. Uniform dispersion of carbon fibers was observed in compounded feedstocks, green and sintered samples. Fiber orientation was quantified at various locations of skin and core of the green and sintered samples. Quantification of fiber orientation showed the best value of more than 90 % of short fibers aligned in green test samples whereas sintered samples demonstrated just above 70 % of fiber alignment in the flow direction in Cu-10 %CF at section N. Overall, the results showed fiber alignment within ± 22.5 ° in both green and sintered samples without significant skin-core effect. Moreover, the calculated mechanical properties increased with an increase in alignment of carbon fiber in the Cu matrix. Conclusively, fiber alignment can be improved by controlling flow of molten feedstock during molding with potentially high mechanical properties of composite.

Methodology

In this study, argon gas atomized commercially pure copper powder with D90 of 21.8 µm purchased from Sandvik International UK was used in feedstock. Carbon fibers (CF) having average diameter and length of 5 µm and 5 mm, respectively were purchased from China Beihai Fiberglass Ltd. A three-component-binder consisting of paraffin wax, polypropylene, and stearic acid was used in the feedstock preparation. All the components possessed characteristics suitable for PIM [22], [23].

Impact & Benefits

Enhanced Mechanical Properties:The alignment of fibers in one direction allows for optimal reinforcement of the matrix, leading to significant improvements in tensile strength, tensile modulus, and flexural strength. Even minor deviations from this alignment can cause a considerable drop in these properties.

Reduction of Skin-Core Effect:Traditional injection molding processes often result in the skin-core effect, where fibers are highly aligned at the surface but randomly oriented in the core. The special mold design in this study significantly reduces this effect, leading to more uniformly reinforced composites.

Material Efficiency: By achieving better fiber alignment, the material properties are maximized, potentially allowing for the use of less material to achieve the same or superior performance, thus reducing costs and resource consumption.

Customizable Properties:The ability to control fiber alignment through factors like fiber content, mold design, and process parameters enables the tailoring of composite properties to meet specific application requirements.

Innovation in Manufacturing:The use of a specially designed mold to create a convergent flow within the mold cavity represents a significant innovation in composite manufacturing. This approach can be adapted and further developed for other types of composites and manufacturing processes.

Research and Development:This study provides a foundation for further research into controlling fiber orientation in metal matrix composites and other types of reinforced materials, potentially leading to more breakthroughs in composite material science.

Findings/Figures and Research Data

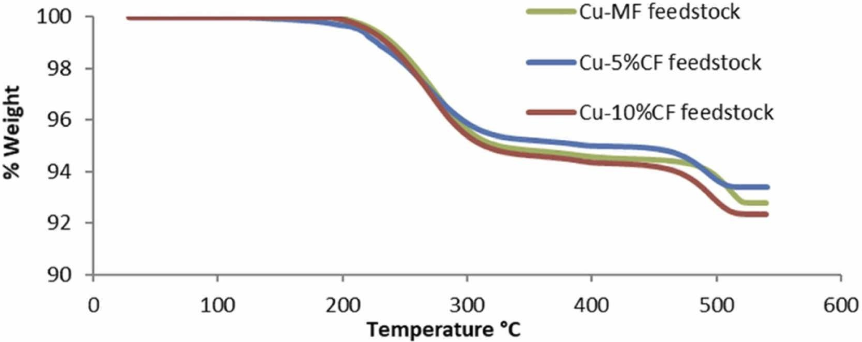

The results from thermogravimetric analyses of Cu-MF, Cu-5 %CF and Cu-10 %CF feedstocks are shown in Fig. 5. Since the binder was used in all feedstocks the TGA curves show a similar pattern. The first drop in weight percent corresponds to the degradation of paraffin wax and stearic acid. The decomposition of paraffin wax starts at around 200 °C. Paraffin wax is removed completely by 300 °C. After 300 °C the drop in weight percentage slows down until around 450 °C. After 450 °C polypropylene starts to degrade thermally and a drop in the TGA curve is noted. The loss in weight stops after about 510 °C which corresponds to complete decomposition of polypropylene. Molding was performed below 200 °C to avoid binder decomposition. A temperature of 170 °C 5 °C was chosen to accommodate for the rise in temperature caused by high thermal conductivity in copper feedstocks [34].

Market Potential

Automotive Industry: The automotive sector continuously seeks materials that offer a high strength-to-weight ratio to improve fuel efficiency and performance. Short fiber reinforced composites with controlled fiber orientation can be used in various automotive components to achieve these goals.

Aerospace Industry: Similar to the automotive industry, aerospace manufacturers require materials that offer high strength, lightweight, and durability. These composites can be critical in the fabrication of aircraft components, leading to weight reduction and improved performance.

Electronics: The electronics industry often requires materials with high thermal and electrical conductivity while maintaining mechanical integrity. Copper composites with aligned short fibers can provide these properties, making them suitable for components like heat sinks and electrical connectors.

Construction:In the construction industry, materials with high tensile strength and durability are crucial. Cementitious composites with aligned fibers have shown improved flexural strength, which can be advantageous for structural applications.

Medical Devices: The medical field requires materials that are strong, lightweight, and biocompatible for devices like implants and surgical instruments. The improved mechanical properties of these composites can make them suitable for such applications.