Sustainable flame retardant coating based graphene oxide and montmorillonite

Author: Faiz Ahmad - March 2023

Siti Maznah Kabeb, Azman Hassan, Zurina Mohamad, Zalilah Sharer, Munirah Mokhtar

Abstract

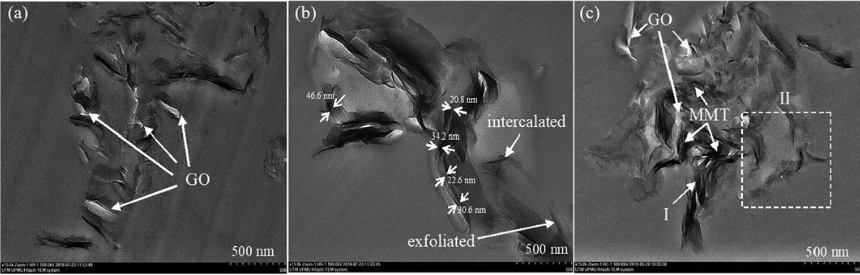

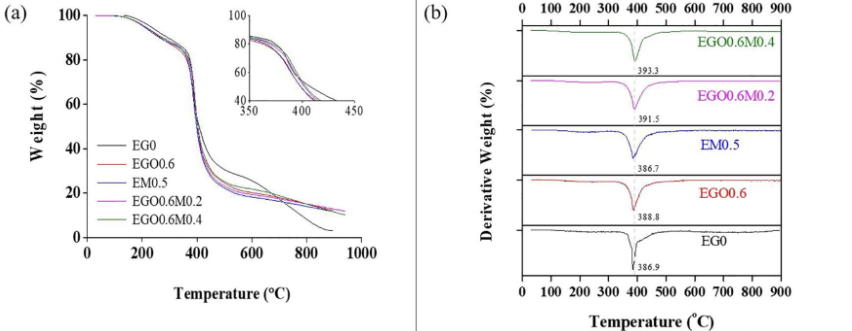

A comparative study of epoxy filled graphene oxide (GO) and montmorillonite (MMT) and its combination on the flame retardancy and thermal stability of epoxy nanocomposite coatings has been investigated. Limiting oxygen index (LOI) and thermogravimetry analysis (TGA) were carried out to determine the flame retardancy and thermal stability properties and clarifying the correlations between different nanofillers fraction. The result suggests that the formation of an efficient hybrid network evidenced by enhanced the flame retardancy as well as thermal stability performance of epoxy nanocomposite coating. The adhesion tape test results revealed that hybrid nanofillers exerts an obviously synergistic effect, demonstrated by the increased in adhesion strength compare to a single nanofillers. Transmission electron microscopy (TEM) revealed a high dispersion of hybrid GO/MMT due to the physical interaction between the nanofillers and epoxy matrix, responsible for the improved of coating's performance.

Methodology

Diglycidyl ether of bisphenol A (DGEBA) epoxy resin (BE-188), polyamine hardener (H2310 polyamine amide) were purchased from by Mc-Growth Chem. Graphene Oxide (UGOXTM) was bought from United Nano Tech Innovations Pvt Ltd. Montmorillonite (Nanomer® 1.44P) was obtained from Nanocor, United Stated.

Impact & Benefits

Enhanced Fire Safety: The primary impact is improved fire safety. Flame retardant coatings significantly slow down the degradation of materials when exposed to fire or high temperatures, preventing early deformation and failure of structures. This ensures the structural integrity of buildings and facilities, providing crucial time for evacuation and firefighting.

Material Performance: The incorporation of nanofillers like montmorillonite (MMT) and graphene oxide (GO) enhances the thermal stability and rigidity of polymers. This not only improves flame retardancy but also enhances the overall mechanical properties of the materials.

Environmental and Economic Benefits: Using polymer nanocomposites and hybrid filler systems leads to superior properties at relatively low costs. The efficient use of materials and improved performance contribute to environmental sustainability by reducing the need for frequent replacements and minimizing waste.

Synergistic Effects of Nanofillers: The combination of GO and MMT in epoxy coatings creates a synergistic effect that significantly enhances flame retardancy and thermal stability. The presence of functional groups on GO offers more active sites for covalent attachment and non-covalent adsorption, which improves the interfacial bonding between nanofillers and the epoxy matrix.

Improved Dispersion and Reduced Aggregation: GO helps prevent the heavy aggregation of nanofillers, ensuring a more homogeneous dispersion in the polymer matrix. This leads to better quality coatings with consistent properties throughout the material.

Enhanced Barrier Properties: The hybrid filler system improves the barrier properties of the coatings, making them more effective at preventing the permeation of gases and other substances. This is particularly beneficial for anticorrosion applications, as reported by Sari et al.

Findings/Figures and Research Data

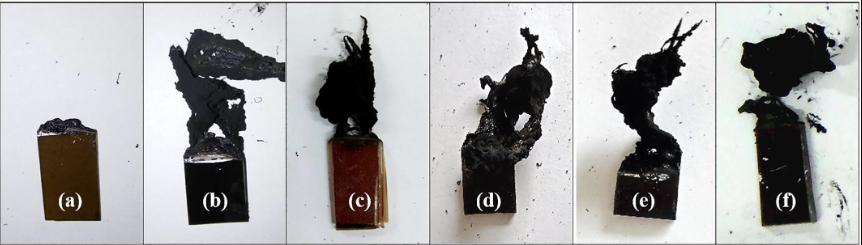

The mechanism of adhesion loss between epoxy and steel has elaborate in detail by George [13]. Adhesion failure when the corrosive electrolyte reaches the coating/metal interface, resulting in the interfacial bonds hydrolysis and coating delamination. It can be seen that the hybrid nanofillers be responsible for more stable and stronger interfacial adhesion at the epoxy/metal interface except for EGO0.6 M0.4 coating. The presence of nanofillers aggregation and agglomerations in some areas at high nanofillers fraction could possibly a root cause of adhesion loss of EGO0.6 M0.4 coating. Simply proclaim the fact that nanofillers filled the voids and crevices between the steel substrates and the polymeric matrix, thus improving the adhesion between the coating and the substrate [14]. Due to the different sizes and shapes of the GO and nanoclay particles, the mixture of both nanofillers can better fill the coating porosity.

Market Potential

Growing Need for Fire Protection: The construction industry has a strong demand for advanced flame retardant coatings to protect structural steel from fire. As urbanization and infrastructure development continue globally, the need for such protective coatings will grow.

Environmental and Regulatory Pressures: Increasing environmental concerns and stringent regulations regarding fire safety standards drive the adoption of more effective and environmentally friendly flame retardant coatings.

Advancements in Material Science: Research and development in polymer nanocomposites, particularly those using GO and MMT, show promising results in enhancing flame retardancy and thermal stability. This ongoing innovation can lead to the development of superior products with broad applications.

Market Segments: The automotive industry can benefit from advanced flame retardant coatings for various components, ensuring passenger safety and meeting regulatory standards.

Economic Benefits: The use of hybrid nanofillers like GO and MMT can lead to cost-effective solutions by improving the efficiency of flame retardant coatings, reducing the amount of material needed, and potentially lowering production costs.