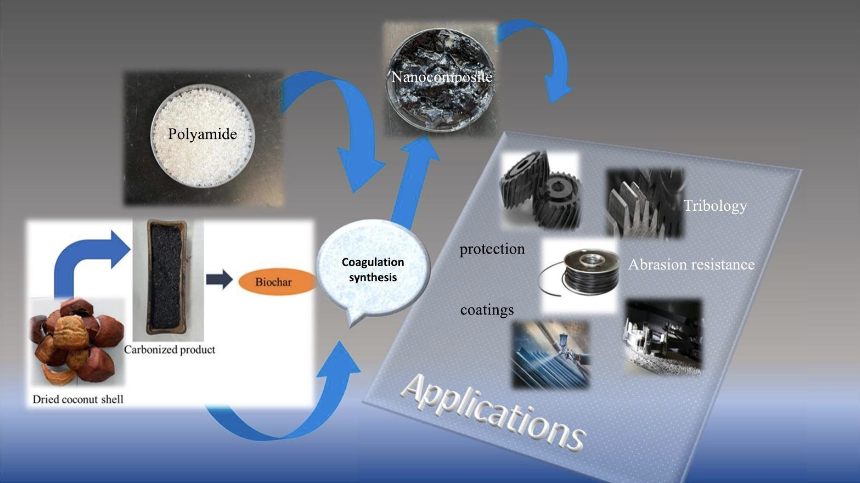

Coconut shell char-based nanocomposites of polyamide-6: An investigation of thermal, morphological, and crystalline properties

Author: Faiz Ahmad - March 2023

Zaib un Nisa, Lee Kean Chuan, Beh Hoe Guan,Saba Ayub

Abstract

This research was intended to investigate the thermal, morphological, and crystalline characteristics of polyamide-6@carbon char-based nanocomposites. The mesoporous nanosized carbon char was prepared in the laboratory via the carbonization method. The parameters of the coconut shell-based biocarbon char were confirmed by surface area and particle size analysis, and X-ray diffraction analysis. The coagulation-processed nanocomposites of polyamide-6 were prepared using synthesized mesoporous carbon char as filler. The obtained filler with a Brunauer-Emmett-Teller surface area of 1517 m2/g and an average pore volume of 2.51 nm was mixed with the polyamide at five different loadings. The coagulation technique was employed for the nanocomposite synthesis. The acquired coagulated nanocomposite was investigated using Fourier transform infrared analysis, thermogravimetric analysis, differential scanning calorimetric technique, and scanning electron microscopy analysis. It was evidenced from the research that loading coconut shell-based carbon char to polyamide-6 can contribute to a 10 °C rise in final degradation temperature with a 4 % loading of filler. The same filler content has contributed to a 5 °C decline in glass transition temperature. A continuous decrease in crystallinity with a rise in the concentration of biochar is indicative of the incorporation of amorphous character. So, it was determined that the thermal, morphological, and crystalline properties have been modified by synthesizing the coagulation-processed nanocomposites with mesoporous biochar of coconut shells.

Methodology

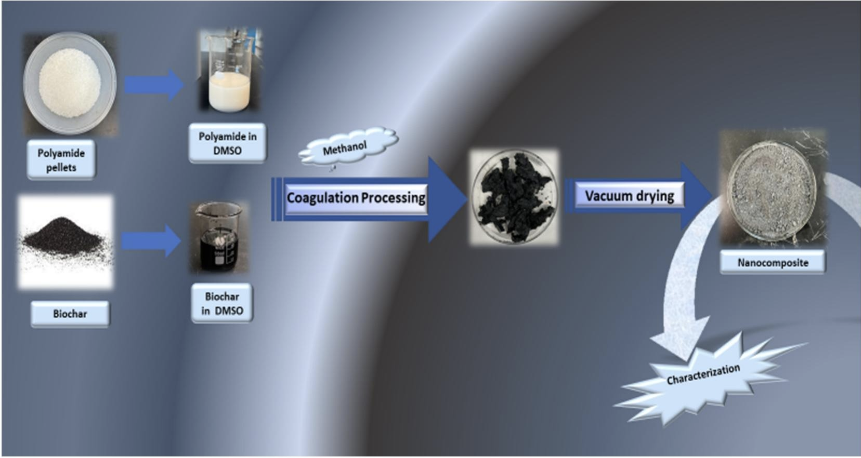

Polyamide-6 pellets were obtained from Sigma Aldrich (density = 1.084 g/mL at 25 °C), Dimethyl sulfoxide (DMSO) Extra pure SLR was supplied by Fischer Scientific (b.p. = 189 °C), Methanol obtained from Friendemann Schmidt sdn bhd (b.p. = 64.9 °Cs) and used as received. The mesoporous biochar (BC) was synthesized from the coconut shell and characterized in the laboratory using the following carbonization technique and performing its physical activation [38]. The BET surface area and pore size of bio-carbon prepared from coconut residue were found to be 1517 m2/g and 2.51 nm respectively [39]. The schematic diagram for the workflow is presented in Fig. 1.The synthesis of PA@BC nanocomposites was achieved by the coagulation technique. Methanol was employed as a coagulant in DMSO solvent media. The characterization of synthesized nanocomposites was performed along with neat polymer to understand the comparative influence on properties

Impact & Benefits

Enhanced Mechanical Properties: The inclusion of bio-based reinforcement materials significantly improves the mechanical properties of base materials. This makes the final products more durable and suitable for various demanding applications.

Sustainability:Utilizing agricultural waste to produce biochar (BC) is an eco-friendly approach that helps in waste management and reduces environmental pollution. It contributes to the creation of sustainable end products.

Industrial Innovation: The unique properties of carbonaceous materials (high aspect ratio, strength, low density) drive innovations in engineering, industrial, and academic fields. This leads to the development of advanced nanocomposites with enhanced properties.

Improved Thermal Stability: Nanocomposites with biochar fillers, such as those prepared from coconut shells, show enhanced thermal stability. This makes them suitable for high-temperature applications.

Crystallization and Morphological Improvements: The addition of biochar affects the crystallization process and morphology of the polymer matrix, leading to improved material properties.

Increased Surface Area and Porosity: Carbon products derived from plant sources, like coconut shells, have fine pore sizes and high surface areas, enhancing their effectiveness as fillers.

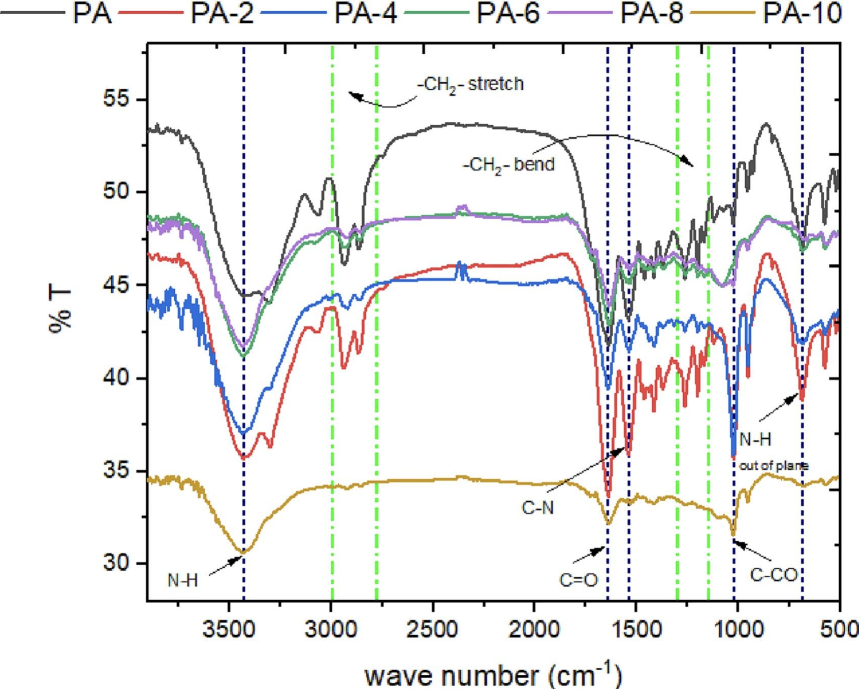

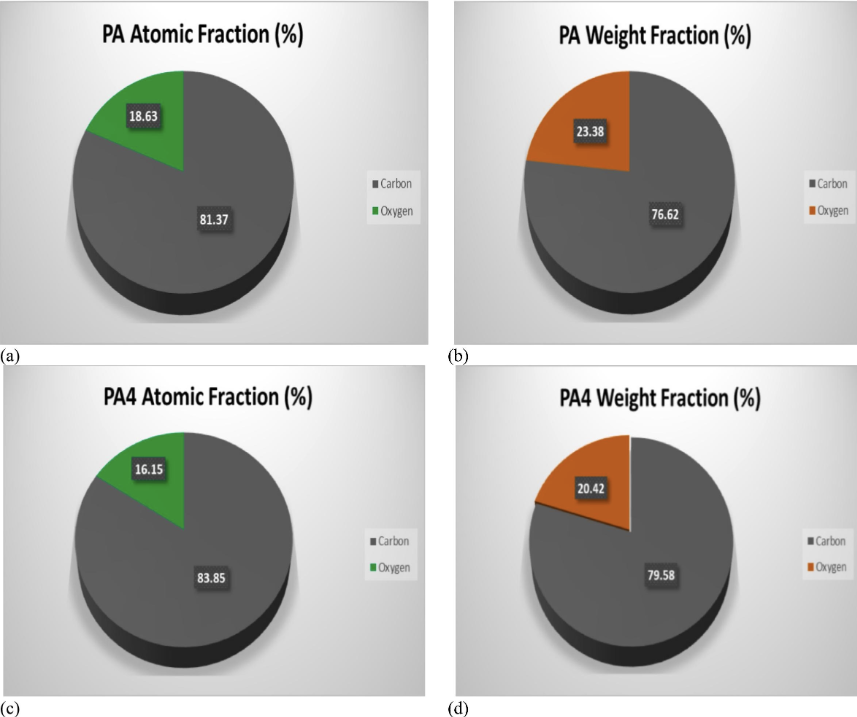

Findings/Figures and Research Data

The synthesis of PA@BC nanocomposites was achieved by the coagulation technique. Methanol was employed as a coagulant in DMSO solvent media. The characterization of synthesized nanocomposites was performed along with neat polymer to understand the comparative influence on properties

Market Potential

Growing Demand for Sustainable Materials There's an increasing global emphasis on sustainable and environmentally friendly materials. Carbonaceous materials from plant sources fit well into this trend, offering biodegradable and renewable alternatives to traditional fillers.

Enhanced Material Properties: These materials significantly improve the mechanical and thermal properties of polymers, making them attractive for high-performance applications.

Economic Production: Carbonization of agricultural waste to produce biochar is a cost-effective method. Utilizing agricultural by-products helps reduce raw material costs, making these materials economically viable for large-scale production.

Innovative Research and Development: Continuous research is leading to innovative applications and improvements in the properties of polymer nanocomposites. This innovation is crucial for maintaining competitive advantage and addressing specific industry needs.

Market Segments and Applications: Sectors like aerospace, automotive, and chemical processing industries require materials with enhanced properties such as high thermal stability and mechanical strength.s