Interface and mechanical properties of graphene/copper composite with sonication induced Au decoration of graphene

Author: Faiz Ahmad - December 2023

Saad Ali, Puteri Sri Melor Megat Yusoff, Norhamidi Muhamad, Waseem Haider, Khurshid Malik, Chowdhury Ahmed Shahed

Abstract

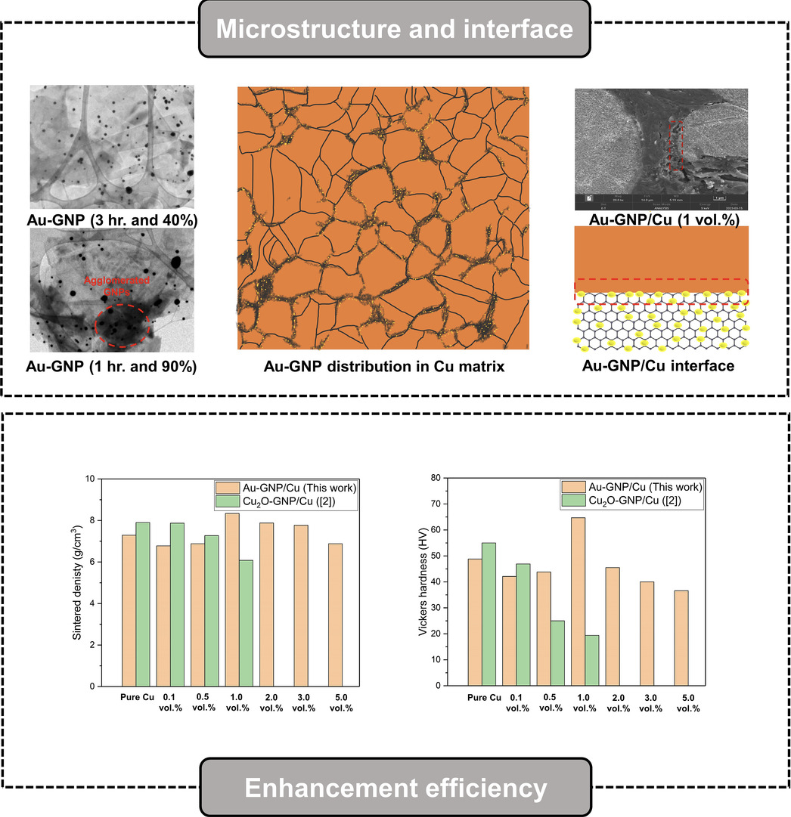

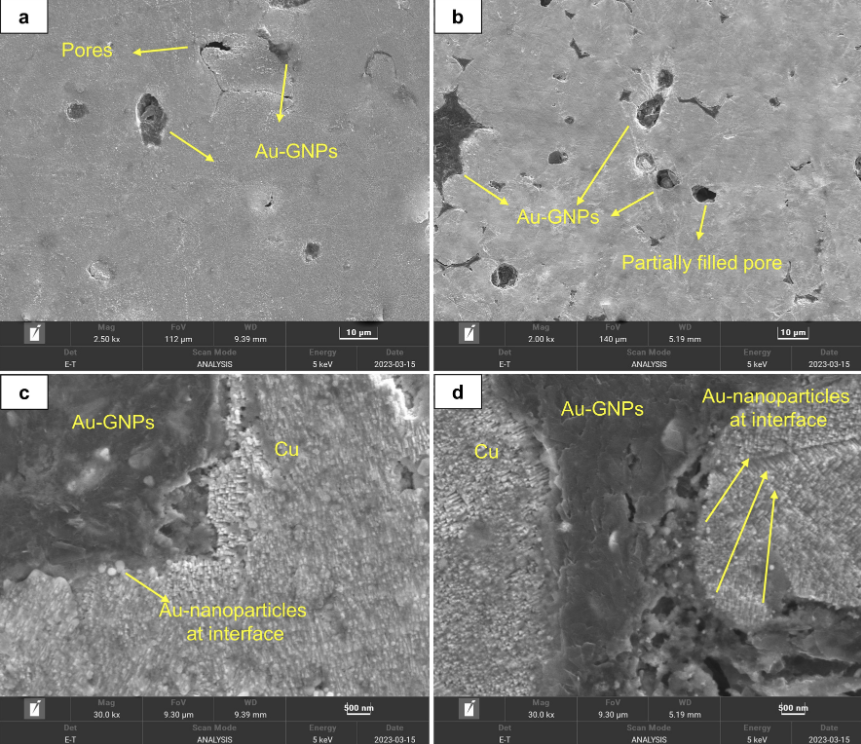

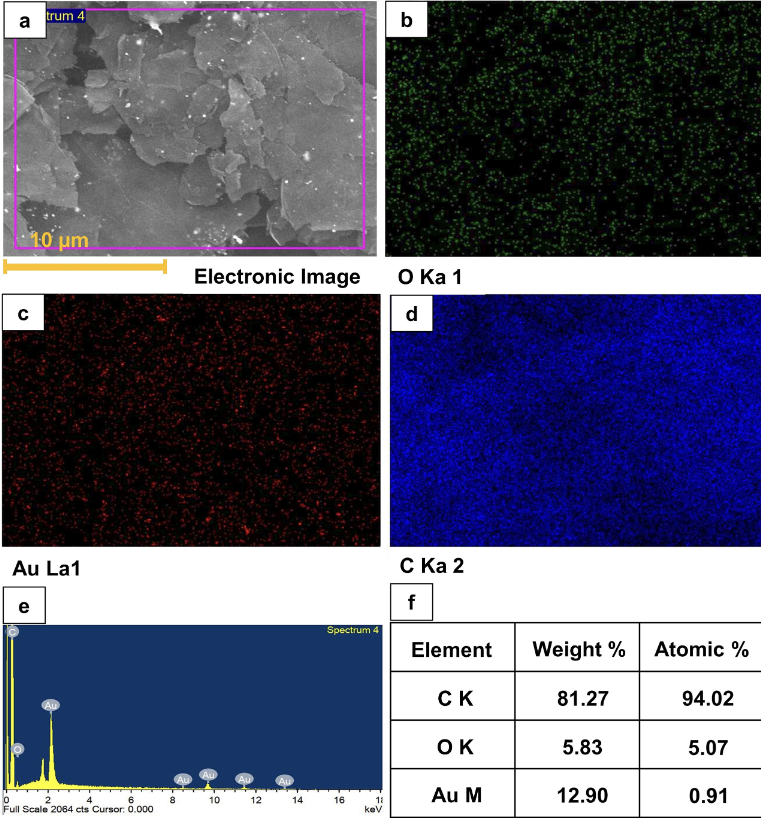

The interfacial interaction between graphene and Cu restricts the efficacious properties' enhancement due to poor wettability between the reinforcement and matrix. Herein, we reported an interface modification strategy by Au decoration of graphene nanoplatelets (Au-GNPs) without carbide/oxide formation. Sonication was used to induce defects in GNPs, which were then decorated with Au nanoparticles and used to fabricate a composite material with Cu (Au-GNP/Cu) via low pressure cold pressing and sintering. Sonication parameters' optimization depicted higher exfoliation of GNPs with lower defects at lower sonication amplitude and higher sonication duration which resulted in relatively monodispersed Au nanoparticles attached to the GNPs' surface. The Au-GNP/Cu composite with 1 vol% showed highest sintered density, hardness and calculated tensile strength which decreased at higher Au-GNP content. The proposed interface design with noble metal nanoparticles acting as bridges between GNP and Cu, opens new horizons for superior mechanical properties of composites.

Methodology

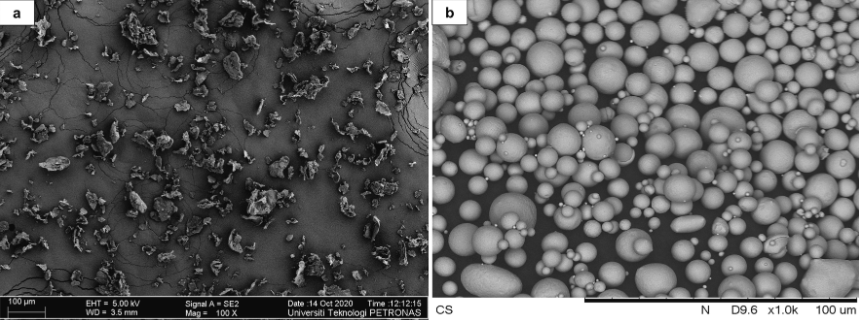

Graphene nanoplatelets (GNPs) with 15 µm lateral size, thickness 6-8 nm and <1% oxygen content, gold (III) chloride trihydrate (HAuCl4.3H2O) =99.9% trace metals basis, and sodium citrate dihydrate were purchased from Sigma Aldrich. Ethanol absolute 99.5% denatured, ChemAr (Alcohol) was purchased from Systerm. The morphology of as received GNPs is illustrated in Fig. 1. Gas atomized copper powder was with D90 of 22 µm, and 99% purity from GoodFellow Cambridge Ltd., UK. Paraffin wax purchased from Abby Chemicals Pvt. Ltd., India, was used for binding the Cu GNP powder mixture.

Impact & Benefits

Enhanced Mechanical Properties: Decorating graphene with metal nanoparticles (NPs) like Ag and Fe3O4 can reduce agglomeration and improve the interaction between graphene and metal matrices. This can lead to composites with higher tensile strength and improved mechanical properties .

Improved Electrical and Thermal Conductivity: Graphene's exceptional electrical and thermal conductivity can significantly enhance the conductivity of the composite materials. This makes graphene-reinforced composites suitable for applications requiring high electrical and thermal performance, such as in electronics and heat dissipation systems.

Overcoming Distribution Challenges:Functionalizing graphene by creating nucleation sites for metal nanoparticles can further improve the attachment and dispersion of these particles, enhancing the composite's mechanical properties .

Interfacial Interaction Enhancement: The presence of metal nanoparticles can act as a bridge between graphene and the matrix, improving the wettability and interaction between the two. This results in composites with better mechanical integrity and performance .

Findings/Figures and Research Data

The nanoindentation data for pure Cu and Au-GNP/Cu composite samples are presented in Table 4. Anton Paar NHT3 nanoindenter was used with a maximum force of 50 mN, loading-unloading rate of 100 mN/min, and dwell time of 10 s. For the nano indentation, the Oliver-Pharr method was employed to measure the hardness and the modulus at localized locations of Cu matrix, Au-GNP and Au-GNP/Cu interface. Here, the HIT is the indentation hardness value, EIT is the indentation modulus, CIT is the indentation creep, HVIT is the equivalent Vickers hardness whereas the elastic property was analyzed by calculating the resistance to plastic deformation i.e., HIT3/EIT2. The higher value of the ratio represents more resistance to plastic deformation. The trend for hardness values obtained for nanoindentation test follows the similar trend as shown by the Vickers micro hardness for all the samples except the pure Cu which demonstrated higher hardness at the nanoscale. In addition, the elastic modulus also follows increasing trend till 1 vol% of Au-GNP/Cu and then drops for samples with higher Au-GNP concentrations [67,68]. Overall, the results of mechanical properties confirmed the effectiveness of Au-GNP reinforcement in the Cu matrix for improving the enhancement efficiency of composite samples.

Market Potential

Demand for High-Performance Materials: Industries such as aerospace, automotive, and electronics require materials with superior mechanical and thermal properties.

Advancements in Nanotechnology: Ongoing research and development in nanotechnology are driving innovations in graphene applications.

Sustainability: Graphene composites offer potential environmental benefits due to their lightweight and high strength, leading to energy savings and reduced emissions in various applications.

Economic Potential: The global market for graphene is expected to grow significantly, with estimates suggesting it could reach several billion dollars by the next decade. The metal matrix composites segment is a key contributor to this growth due to the high demand for advanced materials in various high-tech industries.

Research and Development:Continued R&D is crucial for overcoming existing challenges and unlocking new applications for graphene composites. Collaborative efforts between academic institutions, research organizations, and industry players will be vital in driving innovation and commercialization.