A Comparative Study on the Crystalline and Surface Properties of Carbonized Mesoporous Coconut Shell Chars

Author: Faiz Ahmad - March 2023

Zaib Un Nisa, Lee Kean Chuan, Beh Hoe Guan, Saba Ayub

Abstract

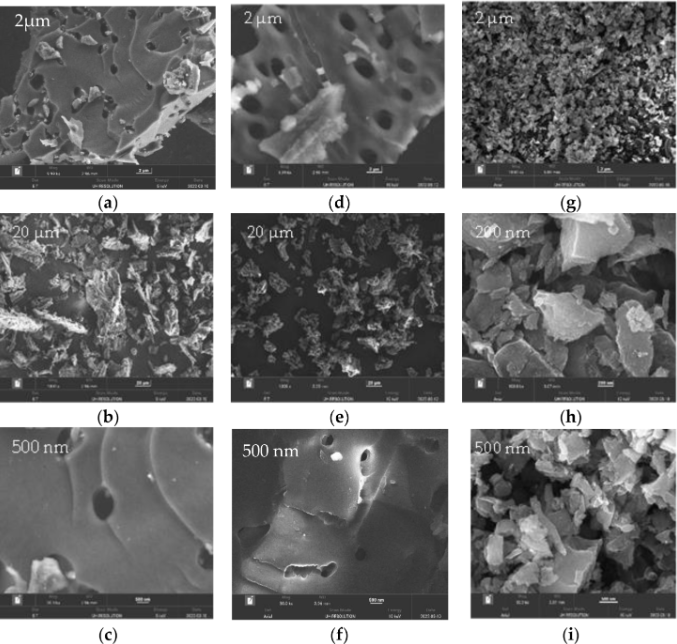

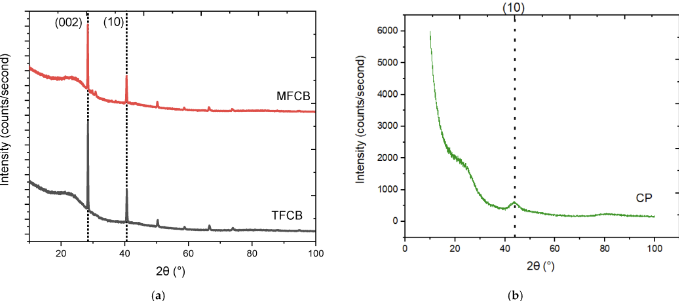

In the present work, the facile thermal decomposition of raw coconut shells was carried out for the exploitation of the role of inert gas in the carbonization process and its role in determining the morphology, crystallographic parameters, and surface area of biochar before activation. The comparative investigation of mesoporous carbonized products synthesized with the muffle and tube furnace was carried out at a similar temperature and an assessment was made with a commercial carbon. The focus of the work was aimed at the interpretation of surface morphology, elemental identification, phase composition, interplanar spacing, full-width half maximum, crystallite size, lateral size, number of layers, dislocation density, microstrain, packing density, crystallinity index, and the specific surface area of the product obtained from two different approaches. It was revealed that the carbonized coconut shell chars obtained from the tube furnace have better characteristics to be activated further for carbon black synthesis. So, the flow of inert gas in a tube furnace is demonstrated to have a key role in improving the attributes of coconut shell chars.

Methodology

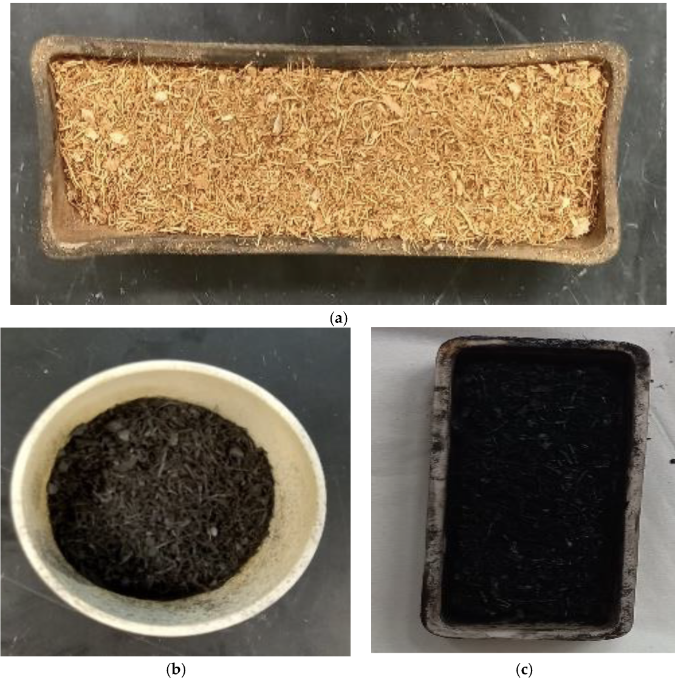

Coconut shells were used as raw materials to produce mesoporous carbon. The coconut shells were cleaned with distilled water. The drying of the cleaned coconut shell was carried out in an oven at 80 °C. The granulation of coconut was carried out in a granulator (SHINI, China Model No. SG-21P) to get smaller-sized naked particles. Carbon nanopowder (CP) with stock no US1078 size (<100 nm) was purchased from the US Research Nanomaterials, Inc. (Houston, TX, USA) for a comparative study.

Impact & Benefits

Economic and Environmental Benefits: Using agricultural waste to produce carbon black is economically advantageous. Agricultural waste is inexpensive and abundant, reducing production costs compared to traditional methods.

Versatility in Applications: Carbon black is extensively used as a pigment and reinforcing agent in rubber and elastomeric materials. It enhances the durability and performance of these materials, which are critical in automotive and manufacturing industries.

Advancements in Technology: Carbon black is being explored for renewable energy applications, including storage devices for electrochemical energy, which are crucial for sustainable energy solutions.

Material Science and Innovation: Carbon black can be dispersed in polymers to increase electrical conductivity, creating composites with improved electrical and mechanical properties. These composites are useful in various industrial applications, including shielding and protective coatings.

Structural Integrity: Carbon black sourced from materials like coconut shells exhibits high strength, low density, hardness, and abrasion resistance, making it suitable for wear applications.

Findings/Figures and Research Data

The smaller the crystalline size, the lower the degree of graphitization will be [36]. The CP is observed to have the greatest interplanar spacing with the greatest FWHM, as the peak is broader with small intensity. It is also observed that most of the calculated microstructural parameters of the CP are not comparable to the MFCB and the TFCB. The reason behind the observed variation is assumed to be the greater graphitic character. The dislocation density is found to be the highest for the CP, which also supports the greater amorphous properties in the commercial product. Similarly, N is calculated to be 12.03 and 12.79 for the MFCB and the TFCB respectively while it is negligible for the CP. As predicted, all the microscopic parameters calculated from the XRD data suggest that the size of the primary atoms in the TFCB is the smallest in the analyzed samples, which emphasizes the carbonization conditions to be favorable in the tube furnace. The X-ray Diffraction analysis was also used to predict the degree of crystallinity using the diffraction intensity ratio of the crystalline peak with the amorphous peak as it related to the respective mass ratios [68].

Market Potential

Cost-Effective Production: Utilizing agricultural waste for carbon black production is cheaper than conventional methods, reducing overall production costs.

Rubber and Tire Manufacturing:Approximately 70% of carbon black is used as a filler and reinforcement in rubber products, especially in the automotive tire industry.

Environmental Applications: Activated carbon black is effective in wastewater treatment and air purification, leveraging its adsorption capabilities.

Technological Advancements: Advances in carbonization and activation techniques enhance the quality and functionality of carbon black.

Market Drivers:Government policies promoting renewable energy and sustainable practices bolster the market for eco-friendly carbon black.