The effects of drilling parameters on thrust force, temperature and hole quality of glass fiber reinforced polymer composites

Author: Faiz Ahmad - March 2023

Khurshid Malik, Woo Tze Keong, and Ebru Gunister

Abstract

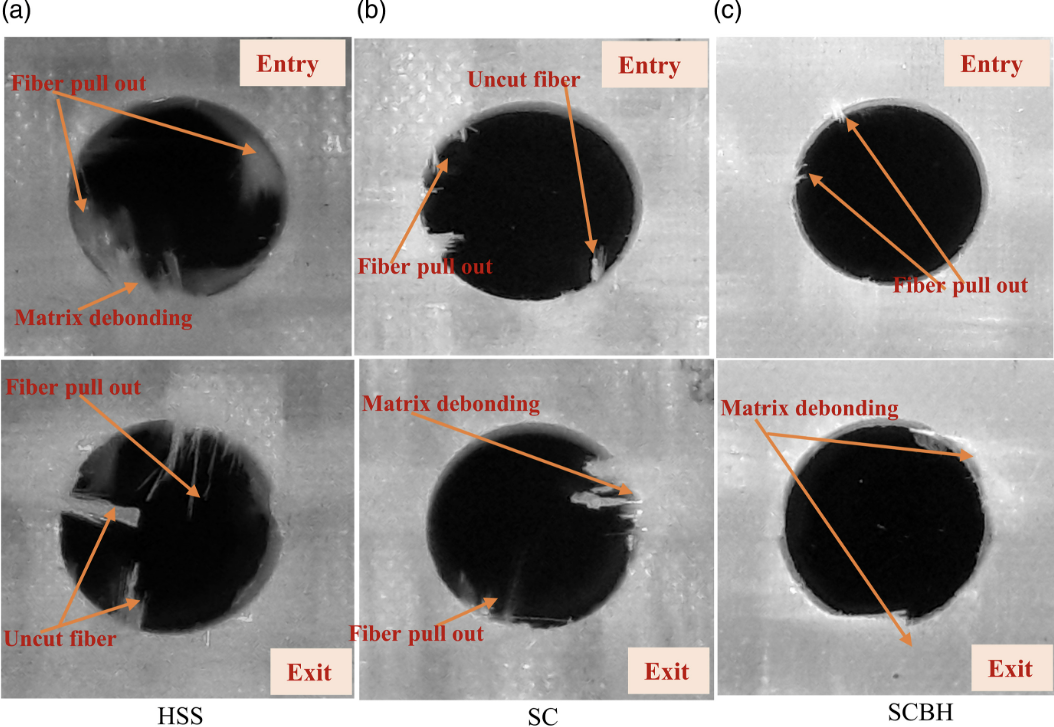

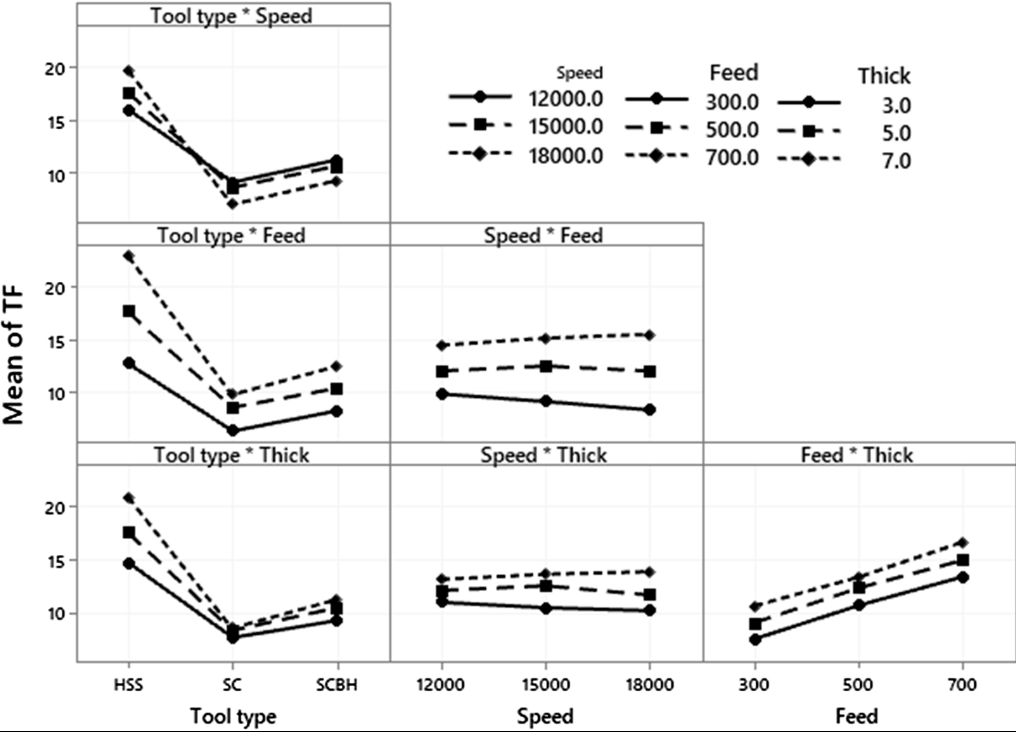

This paper presents an investigation of the drilling performance of glass fiber reinforced polymer (GFRP) composite based on the thrust force, temperature, and delamination factor (at entry and exit of the hole). High-speed steel (HSS), solid carbide (SC), and solid carbide Balinit® Helica coated (SCBH) twist tools were used for the drilling process. Other drilling parameters were high spindle speeds (12,000, 15,000, and 18,000 rpm), feed rate (300, 500, and 700 mm/min), and laminate thickness (3, 5, and 7 mm). ANOVA and response surface methodology were developed to examine the drilling process based on input and output parameters. Results showed that delamination was observed in the form of matrix debonding, uncut fibers, and fiber pull-out. The best drilling performance was achieved by the SC and SCBH tool at a low feed rate (300 rpm) and high speed (18,000 rpm), and high laminate thickness (7 mm).

Methodology

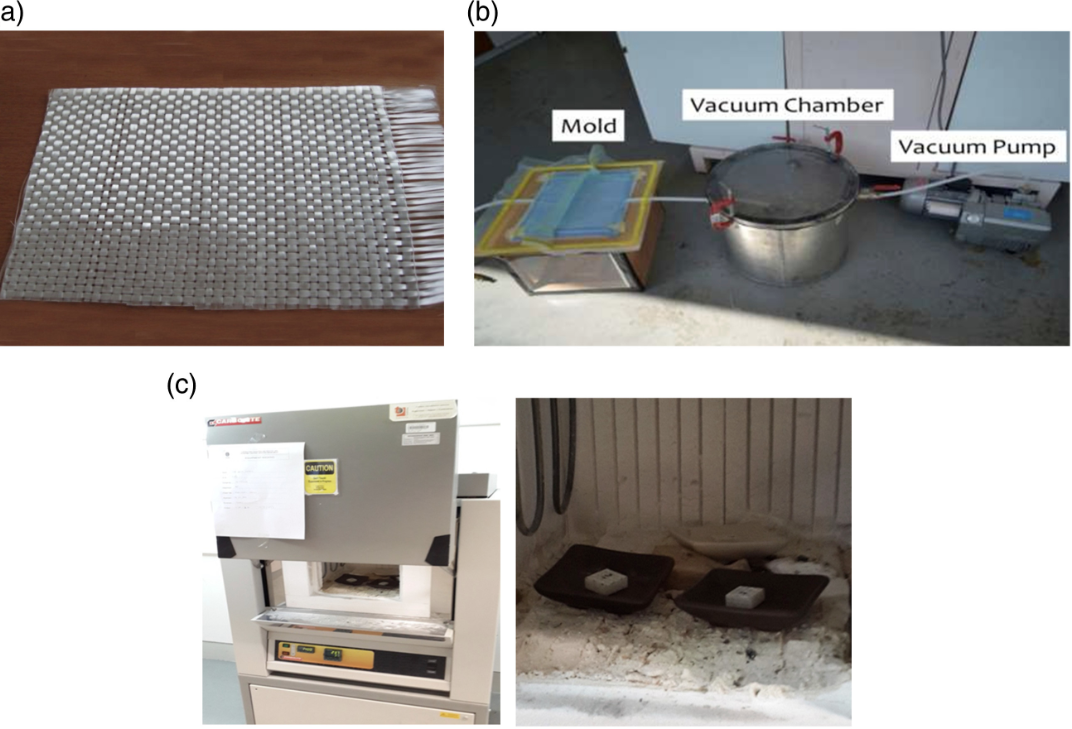

E-glass was purchased from Castmech Technologies Sdn Bhd, Ipoh, Malaysia. It has a fiber diameter of 24 °m, 380 + 40 g/m2 of mass per unit area, 750 yarns per meter with 1.2 kg/m linear density, and fiber density of 2550 kg/m3. Epicote 2820 was supplied by Wee Tee Tong Chemical Sdn. Bhd, Johore, Malaysia, and used as a matrix in the fabrication process. Epicote 2820 consists of two parts: part A, the epoxy, and part B, the hardener. The vacuum infusion molding (VIM) technique was used to fabricate the composites.23 The E-glass and VIM fabrication process is given in Figure 1(a) and (b), respectively. Three GFRP plates were fabricated for each of three different thicknesses with a dimension of 35 cm x 35 cm and thickness of 3 mm, 5 mm, and 7 mm, respectively. The stacked of fiber clothes used in this study were 5 plies of woven glass fiber to produce 3 mm thick composite laminate test samples, 8 plies of woven glass fiber for the 5 mm thick composite laminate test samples, and 11 plies of woven glass fiber were used for the 7 mm thick composite laminate. It was ensured that the vacuum pressure used in the manufacturing process was set to 90 kPa and a motor power of 0.37 kW. The fabrication of the composites was done at room temperature. The impregnation process lasted 10, 12, and 15 min for the 3, 5, and 7 mm thick GFRP composites, respectively. Post-curing of the composites was done for 2 h at 90° in the oven.

Impact & Benefits

Optimization of Parameters: The article provides detailed analysis and optimization of drilling parameters such as speed, feed rate, and tool type. This leads to more efficient drilling processes, reducing time and costs associated with manufacturing.

Minimizing Delamination: By identifying the optimal drilling conditions, the study helps in minimizing delamination, which is a critical issue in GFRP composites. Reduced delamination leads to higher quality parts with better dimensional accuracy and surface finish.

Financial Benefits: Conventional mechanical drilling methods are cost-effective compared to non-conventional techniques. The optimized parameters help in further reducing costs by decreasing tool wear and extending tool life.

Industry Applications: The findings can be directly applied in the aerospace, marine, and automotive industries, which are major users of GFRP composites. Improved drilling processes can enhance the competitiveness of companies in these sectors.

Advanced Analytical Techniques:The use of Analysis of Variance (ANOVA) and Response Surface Methodology (RSM) for examining drilling processes represents a significant scientific advancement. These techniques provide robust data and predictive models that can be used for further research and optimization.

Resource Efficiency: By reducing the rejection rates and improving the efficiency of drilling processes, the study promotes more sustainable manufacturing practices. Less waste generated means a lower environmental impact.

Actionable Insights: The article offers practical recommendations for improving drilling performance, which can be easily adopted by manufacturers. This makes the research highly valuable for immediate application in the industry.

Findings/Figures and Research Data

The result of the validation test is shown in Table 5. From the validation and adequacy test result for the HSS twist drill bit, DF (entry) showed a maximum 17.8% error compared to the experiment result, while DF (exit) the model in equation (8) showed a maximum 37.2% error compared to DF (exit) the experiment result. SC twist drill bit developed model in equation (9) and equation (9) showed a maximum 26.8% error for DF (entry) and 21.9% error for DF (exit) compared to the experiment result. In comparison, SCBH twist drill bit developed model showed the highest 21.5% error for DF (entry) and 32.4% error for DF (exit). The error between the results from the models and the experiment was considered due to external factors such as machine vibration, tool wear, human error, etc., that are not considered. The adequacy test showed that the model might be utilized to predict drilling parameters in the ranges.

Market Potential

Delamination and Machining Issues: The article addresses critical issues like delamination, thrust force, and heat generation during drilling, which are significant challenges in the machining of GFRP composites. Solutions to these problems can lead to higher quality and more reliable composite parts, reducing waste and costs.

Optimization of Drilling Parameters: The research provides optimized drilling parameters (speed, feed rate, tool type) that can minimize defects and improve the quality of drilled holes in GFRP composites. This can lead to better production efficiency and lower rejection rates of parts.

Tool Performance Analysis: By comparing different drill bits (HSS, SC, SCBH) and analyzing their performance, the article offers valuable insights for tool manufacturers to develop and market more effective tools for GFRP composite machining.

ANOVA and RSM: The use of advanced statistical methods like Analysis of Variance (ANOVA) and Response Surface Methodology (RSM) provides robust data and predictive models. These can be leveraged by manufacturers for precise control over drilling operations, enhancing overall process efficiency.

Practical Recommendations:The study offers actionable recommendations for improving drilling performance, which can be directly adopted by manufacturers in relevant industries. This can drive market adoption and lead to broader implementation of the findings.