Microstructure and mechanical performance of low-cost biomedical-grade Titanium-316L alloy

Author: Faiz Ahmad - March 2023

Chowdhury Ahmed Shahed, Ebru Günister, Khurram Altaf, Saad Ali, Abbas Raza, Khurshid Malik, Waseem Haider

Abstract

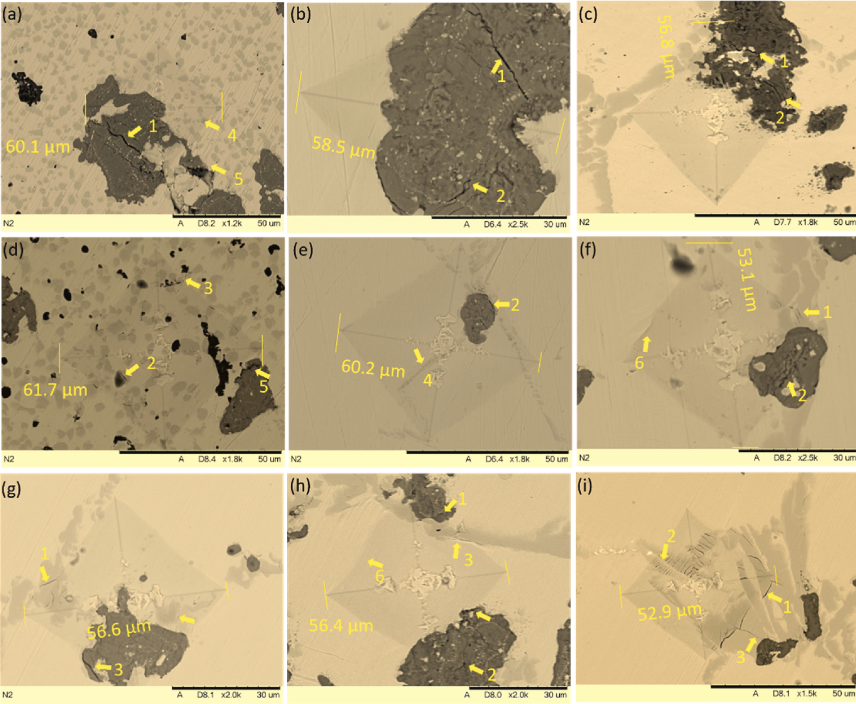

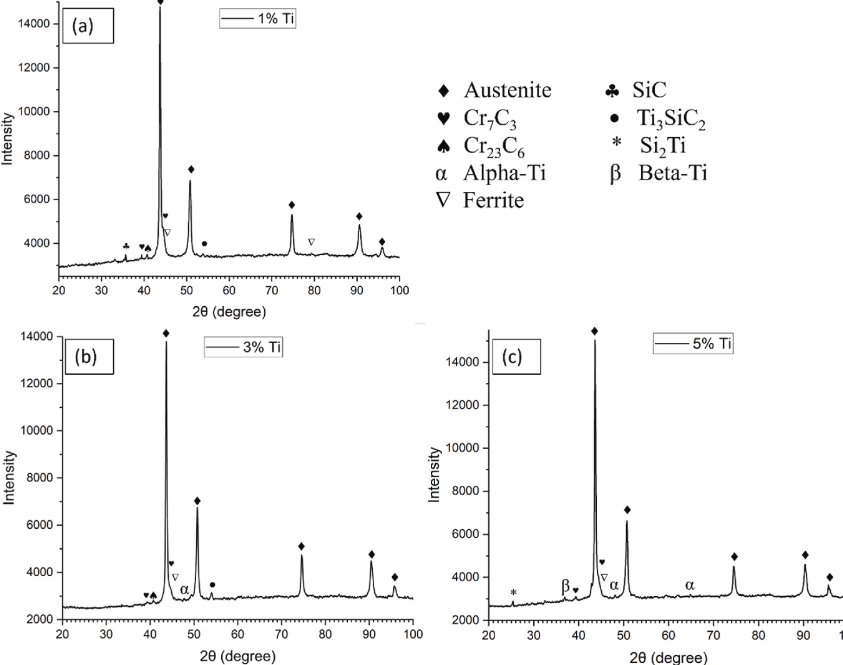

A 316L stainless steel (SS) alloy was developed with 1, 3, and 5 vol% titanium (Ti) reinforcement using the powder injection molding route, representing a low-cost option for biomedical implants. The investigation encompassed 1300 °C, 1350 °C, and 1380 °C sintering temperatures to ascertain the optimal physical and mechanical properties. Both sintering temperature and Ti influenced sintered density, and Ti mitigated the deleterious effects of residual carbon. At higher sintering temperatures, carbon and silicon tended to migrate and accumulate at the brink of Ti, leading to the formation of intermetallic compounds and increased brittleness. Dispersed Ti particles within the 316L matrix acted as nucleation sites and enhanced solid solubility with improved density. An astounding 96.11 % sintered density was achieved at 3 vol% Ti sample sintered at 1380°C. During the tensile test, 5 vol% Ti at 1380°C exhibited a low modulus of 58.9 GPa, which is highly desirable for orthopedic implant application. The XRD, SEM, tensile test, and nano-indentation results collectively provide evidence of beta-titanium formation during the sintering process. Conversely, the sample incorporating 3 vol% titanium, sintered at 1380°C, demonstrated a balanced performance, showcasing 432.94 + 12.8 MPa ultimate tensile strength, 3.06 = 0.17 % elongation, 74.2 GPa modulus, and 322 MPa and 423 MPa 0.2 % offset flexural and compressive yield strengths, respectively. Notably, an improvised wear resistance test underscored its aptitude for sliding wear resistance, solidifying its potential as a promising candidate for biomedical implants.

Methodology

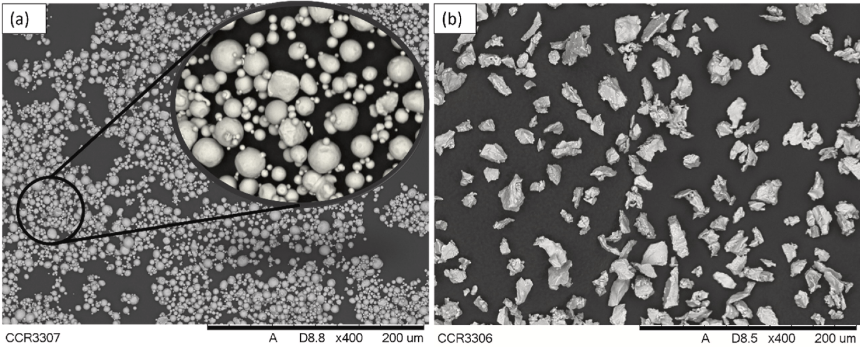

Three different mixing compositions were prepared with 1, 3, and 5 vol% Ti (purity 98 %) and 316L SS (purity 99.5 %). In this experiment, spherical shape gas-atomized 316L SS (Alfa Aesar, UK) and irregularly shaped Ti powder (Alfa Aesar, UK) with particle sizes D50 < 5 µm, D90 < 10 µm and D50 < 18 µm, D90 < 32 µmm is used, respectively. A Hitachi TM3000 scanning electron microscope (SEM) is used to determine the morphology of powders, as shown in Fig. 1, and energy dispersive spectroscopy (EDS) is used to identify the chemical compositions in Table 1.

Impact & Benefits

Complex and Customized Designs:AM's ability to create complex shapes and custom designs is crucial for developing patient-specific implants, leading to more effective and personalized treatments.

Patient-Specific Solutions: Enables the production of implants tailored to individual patient anatomies, improving fit, comfort, and overall patient outcomes.

High Throughput and Cost Efficiency: PIM offers relatively faster production rates and lower costs, making it suitable for mass production of medical components.

Mass Production Capability:PIM is highly effective for producing large volumes of standardized medical components, ensuring consistent quality and performance.

Improved Biocompatibility and Mechanical Properties:The addition of Ti to 316L SS enhances biocompatibility, corrosion resistance, and mechanical properties, making it a promising material for orthopedic implants.

Enhanced Implant Performance: Improved mechanical properties and biocompatibility of Ti-reinforced 316L SS lead to more durable and reliable implants.

Findings/Figures and Research Data

Moreover, gradual wear with applied pressure can accomplish work hardening with few atoms thick from the exposed surface, thus reducing the wear coefficient. Nonetheless, no relation between the wear coefficient and surface roughness was observed. S8 showed the lowest roughness of 0.098 µm followed by S5 (0.103 µmm) after the final pass. On the other hand, all the samples sintered at 1380 °C displayed a low K value. S6 surprisingly had significantly lower K (6.298 x 10-4) than S9 (8.82 x 10-4). In both cases, S1 underperformed by having Ra = 0.0186 µmm and K = 1.59 x 10-3. Sintered temperature and Ti contents both have an impact on Ra and K. Sample sintered at higher temperature and high Ti content shows a relatively smoother surface profile due to the proper diffusion and presence of minimal pores. Similarly, a lower K value has been observed for high-temperature sintered samples. Diffused Ti in the matrix, depleted chromium carbides on the grain boundaries, and formation of intermetallic increase the hardness and suppress the wear tendency. Almost all the samples have shown a steady-state wear coefficient after a 150 m pass.

Market Potential

Niche Applications: High potential in producing custom, patient-specific implants and devices where high complexity and customization are required.

Prototyping and Low-Volume Production: Ideal for prototype development and low-volume production runs.

Cost-Effectiveness:Generally lower production costs compared to AM, making it economically viable for large-scale manufacturing.

Mass Production:High potential for producing large volumes of standardized medical components.

Cost-Sensitive Applications:uitable for applications where cost efficiency is crucial, such as producing standard-sized implants and surgical instruments.