Wear Resistance of Al-12Si Alloys by Reinforcing TiC and TiN Particles

Author: Faiz Ahmad - March 2023

Ali Samer, Malek Ali, Projjal Basu

Abstract

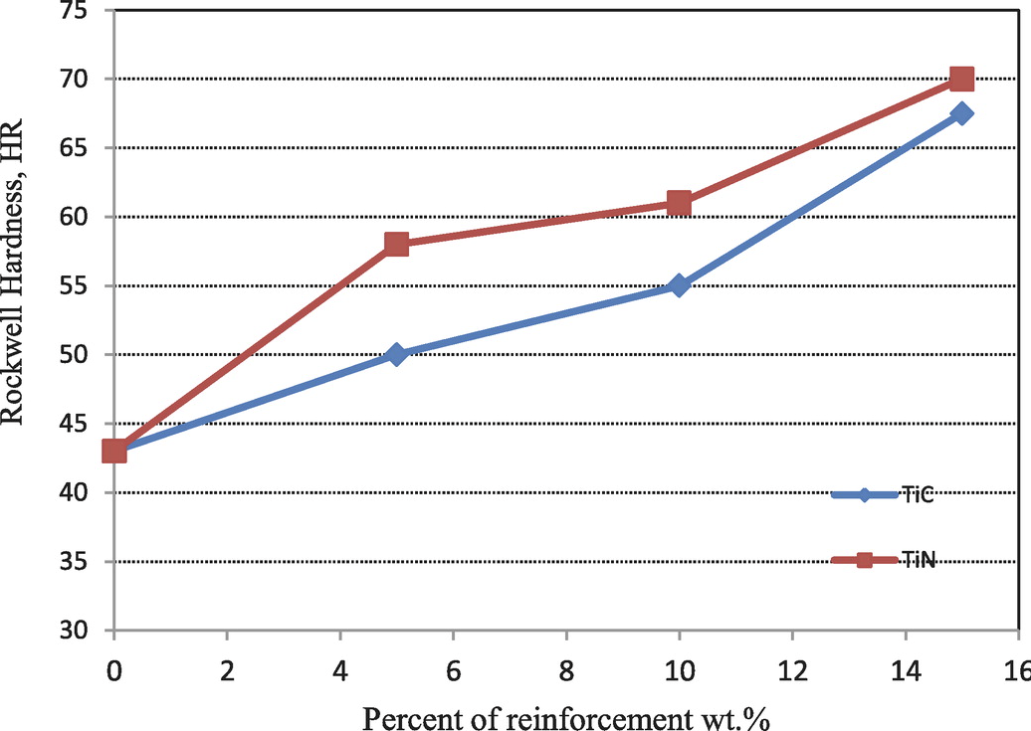

This study presents the mechanical properties of the Al-12Si matrix composite reinforced by various amounts of titanium carbide (TiC) and titanium nitride (TiN) particles. The wear behavior was investigated using a pin-on-disk wear testing machine with varying parameters such as normal load, reinforcement percentage, and track velocity. The results show that the wear of the Al-12Si matrix reinforced by 5, 10, and 15% TiC particles at 150 rpm with 15-N loads was 73x10-3,61x10-3,and 50.5x10-3 mm3, respectively, which is less than the wear for the same composites at 225 rpm with a 15-N load. This is because of the length of rubbing is more in the case of a higher speed. The results also show that the wear of the samples was decreased with an increasing percentage of reinforcement of TiN at both sliding speeds (150 and 225 rpm). The hardness of the Al-12Si/TiC composites with 5% TiC particles was found to be 50, and the hardness of same composites with 15% TiC reinforcements was 67, which is less than the hardness of Al-12Si/TiN composites with 15% TiN reinforcements. The composites before the wear test showed a uniform distribution of TiC and TiN particles through the cross section of the specimens and finer surfaces compared with matrix composite after the wear test. The mechanical properties such as hardness and wear resistance are observed to be increased considerably compared with the matrix composite.

Methodology

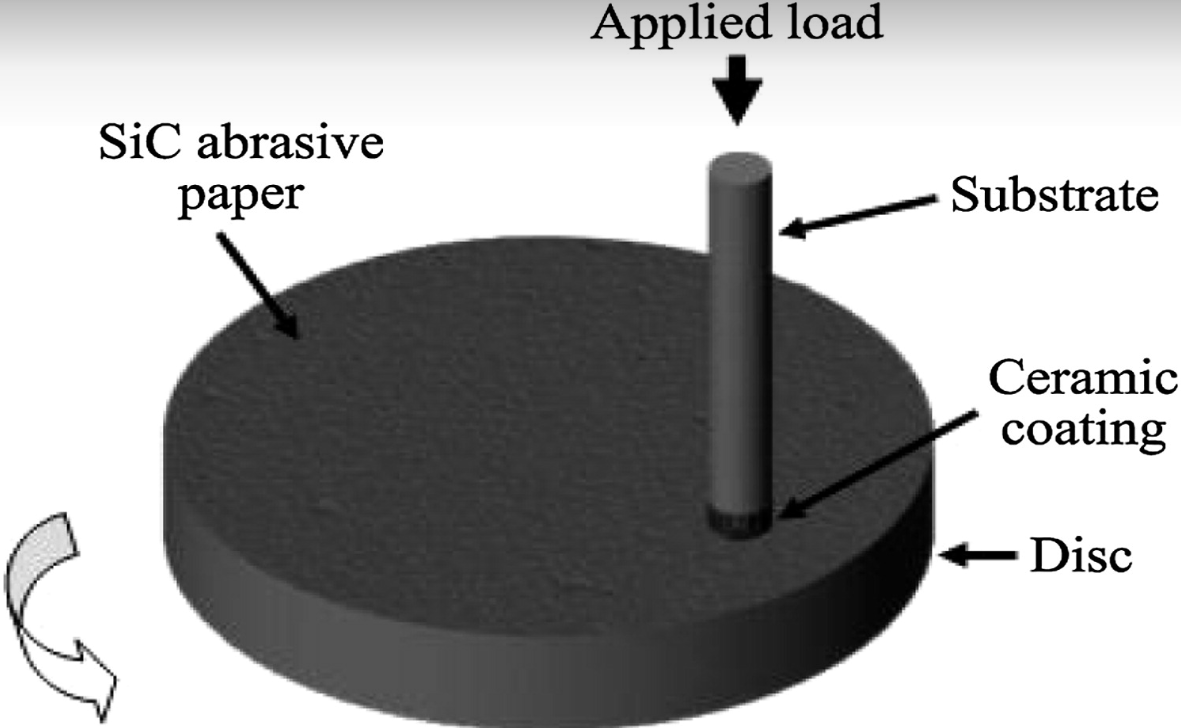

The Al-12Si was used as matrix material. The TiC and TiN particles were used as reinforcement in the Al-12Si alloy. The particle size of TiC and TiN was approximately 10 ???m, and the particles were supplied by Stream Chemical (Chengdu City, China). In the current study, the synthesis of the aluminum matrix composite was carried out using powder metallurgy. Mixtures of Al-12Si powder with compositions of 5, 15, and 25% by weight TiC and 5, 15, and 25% by weight TiC were prepared. Mixtures were subjected to normal mixing for 2 h at a speed of 20 rpm and then were compacted into pellets by 750 MPa applied for 3 min. The powder mixture (0.5 g) was pressed into one pellet in a steel mold of 10-mm internal diameter. Zinc stearate was used as a die wall lubricant. The green compacts of the Al-12Si/TiC and Al-12Si/TiN composites were sintered by a tube furnace under a protective argon gas atmosphere for 3 h at 600 °C. The scanning electron microscopy (SEM) technique was used for microstructure examination of the composites. Hardness measurement was carried out to investigate the influence of the particulate weight fraction of TiC and TiN particles on the matrix hardness. A Rockwell macro hardness machine was used to measure the samples hardness. A load of 60 kg was applied and held for 5 s. To eliminate errors caused by local nonhomogeneity, five different points were taken for each sample, and the average value was taken. A pin-on-disk machine (Fig. 1) was used to measure the wear resistance of the samples, in which the base frame holds the disk carrier spindle and the pin carrier assembly in a fixed orientation. The two assemblies are designed to maintain alignment between the pin and disk specimens so that flat-on-flat geometry can be used. The test was carried out by a pin-on-disk under dry sliding conditions, in ambient air at room temperature at ~25 °C (Chandrashekharaiah and Kori 2009). The disk was rotated by a direct current (DC) motor, with two sliding rotation speeds of 150 and 225 rpm for 282.6-m distance per sample, with a supplied load of 10, 15, and 20 N at 60-mm distance from the center of the disk. These investigations were performed on the influence of different conditions (load, sliding speed, holding time, and distance), as well as different reinforcements and percentages. Therefore, the unreinforced eutectic Al-Si alloy was used as a reference.

Impact & Benefits

Weight Reduction: The high strength-to-weight ratio of Al-Si alloys allows for lighter components, leading to overall reduced weight in machines and vehicles.

Improved Performance: Al-Si alloys' resistance to corrosion ensures longevity and reliability of components, reducing the need for frequent replacements and maintenance.

Broader Application Scope: Good castability of Al-Si alloys enables their use in complex shapes and designs, enhancing their applicability across various industries, including aerospace, automotive, railways, and cycling.

Reinforcement Additives: Studies show that adding reinforcements such as Al2O3, SiO2, B4C, TiN, and TiC to Al-Si alloys improves wear resistance significantly. This leads to longer-lasting components, reducing downtime and replacement costs.

Lower Volume Loss: Research indicates that reinforced Al-Si alloys exhibit lower wear rates compared to unreinforced alloys. For example, Al-12Si/TiN composites show reduced wear even under high loads and sliding speeds, leading to better performance in demanding applications.

Lower Friction Coefficients: Reinforced Al-Si alloys, such as those with TiN particles, show lower friction coefficients and decreased adhesion between sliding pairs, which is beneficial for applications requiring smooth and consistent motion.

Findings/Figures and Research Data

The reinforcement with TiC and TiN particulates was found to be attractive for the aluminum matrix because of its good wettability, which can result in a clean and strong interface, enhances the resistance of the matrix to penetration, and reduces subsequent removal of material (Abdulhaqq et al. 2009; Albiter et al. 2003). While measuring the extent of wear, the two surfaces are brought into sliding contact at the beginning; the soft aluminum matrix between the TiC or TiN particles undergoes severe deformation. The uniform distribution decreases the amount of matrix between the TiC particles, which leads to a decrease in the deformation as shown by the results of wear measurements for composites. The number of cracks between the particles and aluminum matrix increases with increasing sliding distance, and sliding speed leads to pull-out of reinforcements and form wear debris (Yang et al. 2003).

Market Potential

Aerospace Industries: Enhanced wear resistance and reduced weight contribute to fuel efficiency and durability.

Automotive Industries: Improved engine components and structural parts can lead to better performance and longer lifespan.

High-speed trains: Brake rotors and other components benefit from the improved wear resistance.

Bicycles: Lightweight yet strong components improve performance and endurance.