Investigation of Rheological Behavior of Low Pressure Injection Molded Stainless Steel Feedstocks

Author: Faiz Ahmad - January 2016

Muhammad Aslam, Puteri Sri Melor Binti Megat Yusoff, Khurram Altaf, Mohd Afian Omar, H. P. S. Abdul Khalil, M. Rafi Raza

Abstract

The purpose of this research is to investigate the influence of different powder loadings of 316L stainless steel (SS) powders on rheological behavior of feedstocks required for low pressure powder injection molding (L-PIM) process. The main idea consists in development of various formulations by varying 316L SS powder contents in feedstocks and evaluating the temperature sensitivity of feedstock via flow behavior index and activation energy. For this purpose, the irregular shape, spherical shape, and combination of both shapes and sizes (bimodal approach) of 316L SS powders are compounded with wax based composite binder. Moreover, the influence of elemental nanosized boron (nB) addition (up to 1.5 wt.%) on rheological properties of irregular shape 316L SS powders is also evaluated using capillary rheometer method. It is observed that rheological parameters for solid powder loading of powder gas atomized (PGA) and bimodal powder P25/75 316L SS underwent sudden change from PGA-69 vol.% to PGA-72 vol.% and P25/75-67 vol.% to P25/75 316L SS 70 vol.%, respectively. Thus it is concluded that PGA-69 vol.% and P25/75-67 vol.% are optimal powder solid loadings corresponding to the lowest values of activation energies.

Methodology

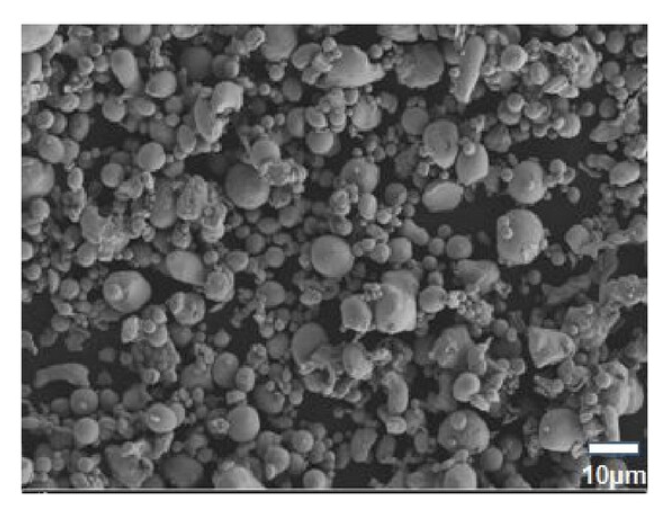

The starting materials used in this research are powder gas atomized 316L stainless steel (PGA 316L SS), powder water atomized 316L stainless steel (PWA 316L SS), and nanosized boron (nB) powders. Three main formulations are designed and developed comprising PGA, PWA-nB powder mixture, and bimodal mixture of two powders PGA and PWA in the ratio of 25 vol.% and 75 vol.% (P25/75 316L SS) as shown in Figure 1. The bimodal powder mixtures play a vital role in shape retention and save the cost up to 10% as compared to monosized spherical powder [14]. D50 size of PWA, PGA, and nB was measured using MASTER SIZER 2000 and these are 6.9 um, 20 um, and 60-80 nm, respectively. The composition of SS powder and binder ingredients to prepare various feedstocks was selected as shown in Table 1. The polypropylene (PP) component of binder is used as backbone, paraffin wax (PW) is used as flow promoter, and stearic acid (SA) is used as surfactant. Figure 2 shows DSC and TGA analysis for binder components used for making various formulations. It is evident from Figure 2(a) that melting temperature for SA, PW, and PP is 65°C, 55°C, and 160°C, respectively. Figure 2(b) shows that the binder starts to decompose at 200°C and ends at 450°C~470°C. Hence the solvent and thermal debinding cycles would be designed within these temperature limits.

Impact & Benefits

High Surface Quality and Close Tolerances: PIM produces parts with excellent surface finishes and precise dimensions, reducing the need for secondary operations.

Reduced Waste: The ability to produce near-net-shape components minimizes material wastage, leading to cost savings and more sustainable manufacturing processes.

Lower Energy Consumption: The PIM process, especially with low-pressure injection molding, typically consumes less energy compared to traditional PM processes.

Multiple Binder Systems: A variety of binder systems allows for customization based on the shape, size, and distribution of powders, enhancing the flexibility of the manufacturing process.

Superior Mechanical Properties: PIM parts typically exhibit excellent mechanical properties, such as high strength and durability, making them suitable for demanding applications.

Reduced Emissions: The efficient use of materials and energy in PIM leads to lower emissions compared to traditional manufacturing methods.

Findings/Figures and Research Data

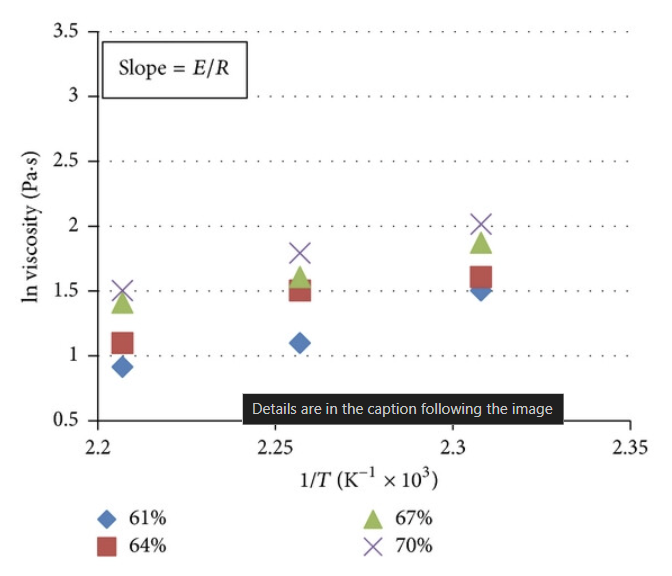

It is clear that value of flow behavior index varies from 0.35 to 0.63 and this range decreases with increase of solid loading. This behavior shows that the value of n is lower for P25/75-70 and it is critical powder-to-binder ratio for powder injection molding. However, the activation energy for these formulations decreases with the increase of solid loading up to 67 vol.% and then increases again. So P25/75-67 is to be considered the optimal powder-to-binder ratio for low pressure molding. The thermal behavior of P25/75-67 is more stable as compared to P25/75-61 because of large viscosities range as shown in Figure 9.

Market Potential

High Precision and Complexity: High surface quality and close tolerance reduce the need for post-processing, saving time and costs.

Cost Efficiency: Reduced material waste and efficient use of raw materials.

Technological Innovations:Advances in binder systems and feedstock formulations improve flowability and reduce defects.

Environmental Benefits:Lower energy consumption compared to traditional manufacturing methods.