An investigation on thermal performance of wollastonite and bentonite reinforced intumescent fire-retardant coating for steel structures

Author: Faiz Ahmad - December 2019

Sami Ullah, Nurul Haswina bt H. Merican, Eugenio Onate, Abdullah G. Al-Sehemi, Guan Heng Yeoh

Abstract

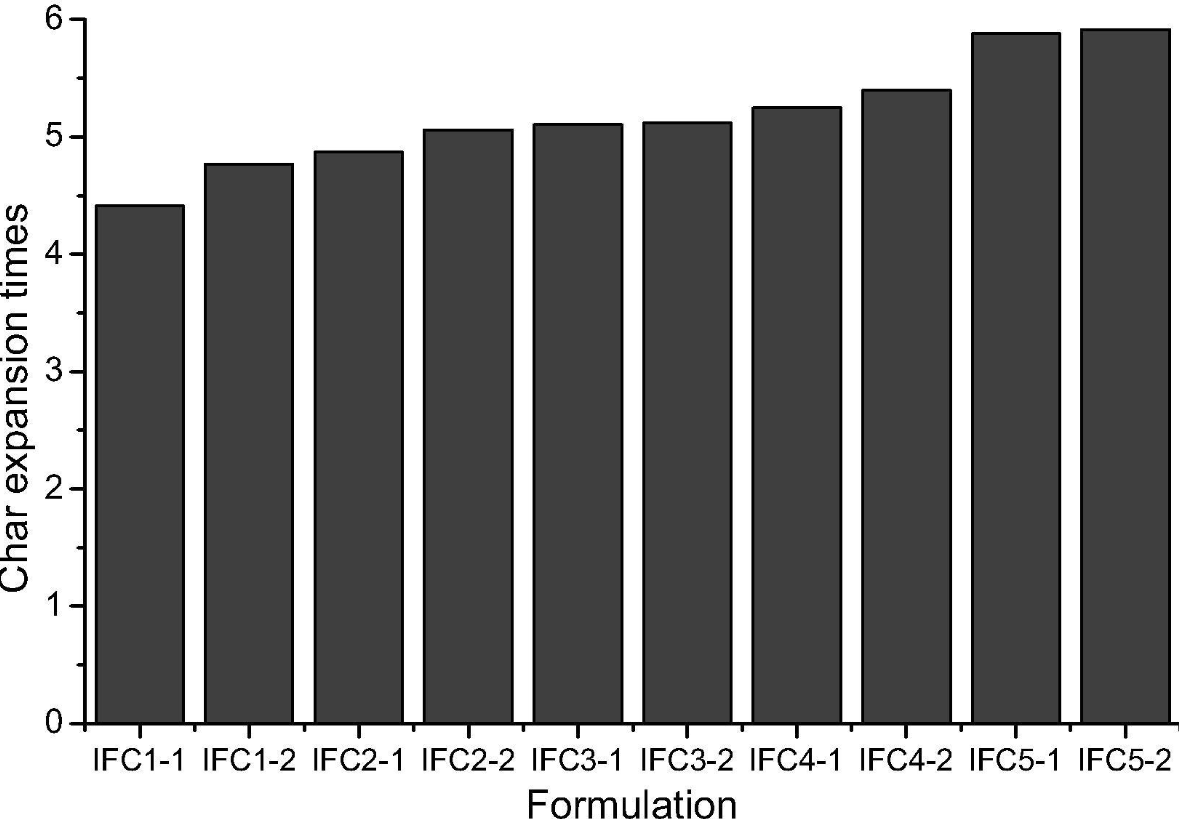

This research investigates the synthesis of new formulations of intumescent coating with improved thermal performance for steel structures. The coating formulations were based on the expandable graphite reinforced with wollastonite and bentonite. Ten samples of five formulations were synthesized by varying grinding time duration between 1 and 2 min. To analyse the substrate temperature of coated steel, fire test was performed according to ASTM-E119. The char morphology was observed by Field Emission Scanning Electron (FESEM) and Transmission Electron Microscopy (TEM). FTIR and X-ray Diffraction (XRD) test is conducted to analyse the composition of the residual char. The residual char mass was perceived by Thermogravimetric analysis (TGA) of the coating. X-ray Photo Electron Spectroscopy (XPS) was utilized for binding energy and elemental composition of the char. One-hour fire protection test showed 166 °C, the lowest substrate temperature of IFRC5-2 and 40.46% residual mass was obtained by TGA analysis. XRD analysis showed that residual char has aluminum borate and borophosphate and confirmed by functional group analysis using and FTIR. FESEM and TEM illustrated that char relates to hexagonal particles of wollastonite. XPS analysis of IFRC5-2 showed the carbon and oxygen contents were 41.40% and 51.20%. Pyrolysis-Gas Chromatography-Mass Spectrometry (Pyrolysis GC-MS) results showed IFRC-5 produced less concentration of the gaseous products compared to IFRC-C. The formulations developed by grinding solid ingredients for 2 min showed improved thermal performance compared with the formulation produced by grinding solid ingredients for 1 min. Longer grinding time and higher amount of filler improved the thermal properties of the intumescent coating.

Methodology

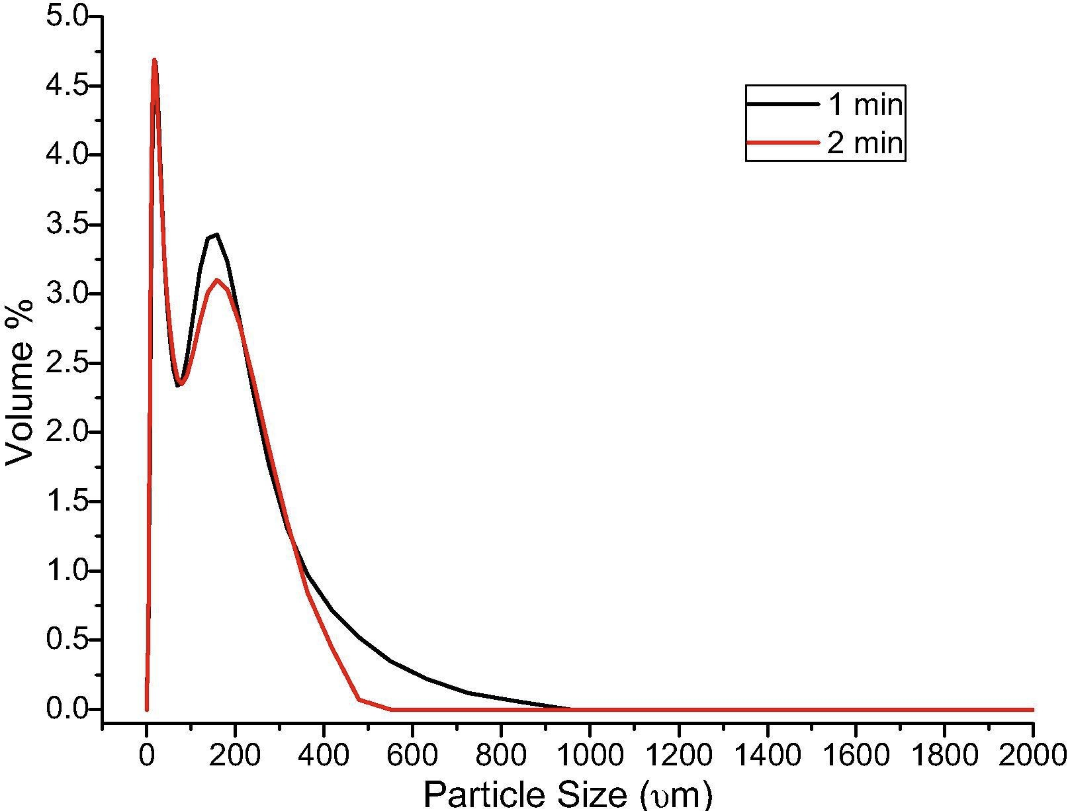

All ingredients of the coating formulations were grinded for two different times (one and two minutes) to study the effects of particle size on the coating performance. The particle size distribution was performed using particle size analyser and results are illustrated in Fig. 2. Ten formulations of IFRCs were developed and their composition is given in Table 2. Precisely weighed quantity of coating ingredients were blended by a shear mixer at 20 rpm. The blended mixture of ingredients was dispersed in epoxy resin for 30 mins and during the last 15 min, hardener was incorporated in the blend to evade cross-linking of epoxy with hardener. The developed IFRC was used on sandblasted steel substrate in size of 100 x 100 x 1.5 mm using a brush. The coating was allowed to cure for one week at room temperature to ensure complete hardened coating. The procedure was adopted to develop all coating formulations studied.

Impact & Benefits

Delay in Structural Failure: The primary impact is the improved fire resistance of structures. By delaying the temperature rise to critical failure levels, these coatings provide more time for evacuation and fire control, reducing fatalities and injuries during fires.

Cost Savings: Reducing fire-related damages can result in significant savings on repairs and replacements. Moreover, lower insurance premiums can be expected for buildings with advanced fire protection systems.

Material Innovation: The use of wollastonite and bentonite represents a technological advancement in fire retardant materials, potentially leading to further innovations in the field of fire safety.

Heat Shielding: Enhanced heat shielding properties protect the steel from rapid temperature increases, thus prolonging the structural integrity during a fire.

Strength and Durability: The inclusion of ceramic fillers like wollastonite and bentonite improves the mechanical properties of the coating, making it more durable and effective.

Safety Improvements: Providing more time for evacuation and firefighting efforts can significantly improve safety outcomes during fire incidents.

Findings/Figures and Research Data

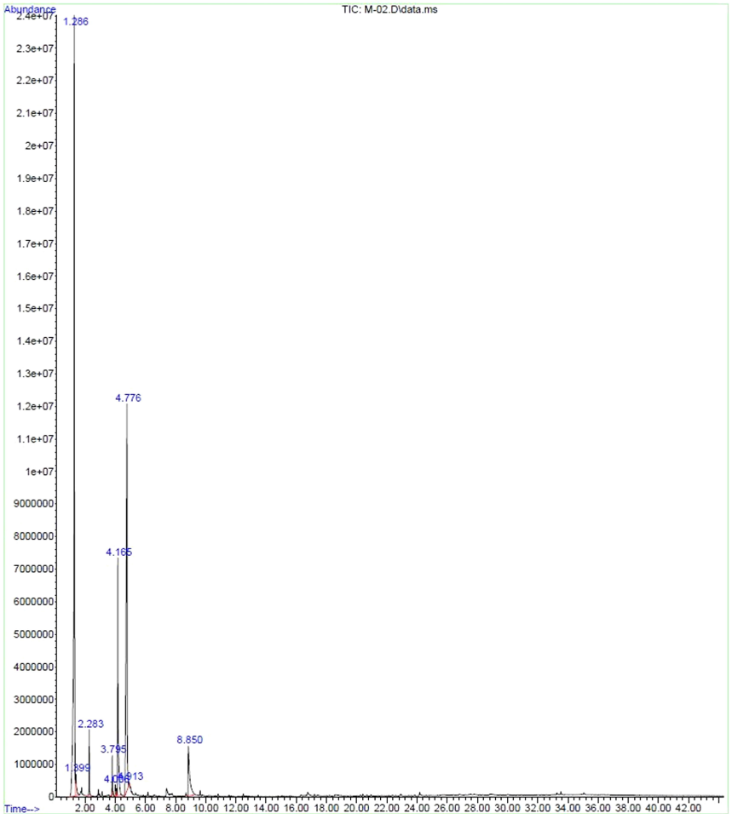

IF5-2 was selected to be examined with Py-GCMS. The results showed 9 peaks as given in Table 7 and the chromatogram was demonstrated in Fig. 25. The 4%weight of wollastonite and bentonite (1:1) reduce the emission of the phenol 12.85% at 4.165tR, which is 54.31% less than observed for IF1-2. Nine gaseous products were noted during the GC-MS test which are less than the control formulation IF2-1. The main gaseous products were obtained from the thermal disintegration of IF5-2 were 1-Octadecanamine, Phenol, Benzyl Alcohol, and 1,3-Cyclopentadiene as the chromatogram was illustrated in Fig. 25. The addition of inorganic fillers wollastonite and bentonite (1:1) facilitated to minimize the emission of gaseous compounds to create dense and spongy char which sheltered the underlying steel substrate throughout fire of intumescent coating.

Market Potential

Increasing Awareness and Regulatory Requirements: Governments and international bodies are imposing stricter fire safety regulations, particularly for buildings, industrial facilities, and public infrastructure. Compliance with these regulations is driving the demand for advanced fire protection solutions like IFRCs.

Technological Advancements: The incorporation of materials like wollastonite and bentonite in IFRCs enhances their fire-retardant properties, making them more effective in delaying the failure of structural steel during fires. This technological edge makes these coatings attractive to the construction and industrial sectors.

Construction and Industrial Growth: Rapid urbanization and industrialization, especially in emerging economies, are driving the construction of new buildings and industrial facilities, all of which require robust fire protection solutions.

Economic and Environmental Benefits: Intumescent coatings can be more cost-effective compared to other fire protection methods, especially when considering the long-term benefits of preventing fire damage and reducing maintenance costs.

Competitive Landscape: Numerous companies are investing in the development and commercialization of advanced IFRCs. This competitive landscape fosters innovation and improves the availability and affordability of these coatings.