Effect of boric acid and melamine on the intumescent fire-retardant coating composition for the fire protection of structural steel substrates

Author: Faiz Ahmad - September 2012

Sami Ullah, P. S. M. Megat Yusoff

Abstract

Intumescent coating is an insulating material designed to decrease heat transfer to a substrate structure. The coating presented in this research article was based on expandable graphite, ammonium polyphosphate, melamine, and boric acid. Bisphenol A epoxy resin BE-188 was used as a binder with ACR hardener H-2310 polyamide amine. Different formulations were developed to study the effect of expansion and heat shielding after fire testing. The coating was tested at 950 °C for 1 h. The results show that the coating was stable and well bonded with the substrate. The coating was characterized with thermogravimetric analysis (TGA, Parkin Elmer, Norwalk, CT, 06859, USA), Fourier transform infrared (FTIR, Nicolet 400 D Shimadzu spectrometer) spectroscopy, X-ray diffraction (XRD, Bruker D8 advance Diffracto meter, Bruker Germany), and scanning electron microscopy (SEM, Carl Zeiss Leo 1430VP, UK). The morphology of char was studied by SEM on the coating after fire testing. XRD and FTIR spectroscopy showed the presence of graphite, boron phosphate, boron oxide, and sassolite in the residual char. TGA (Pyris 1, manufactured by Parkin Elmer, Norwalk, CT, 06859, USA) and differential thermal gravimetric analysis (DTGA) showed that boric acid enhanced the residual weight of the intumescent fire-retardant coating.

Methodology

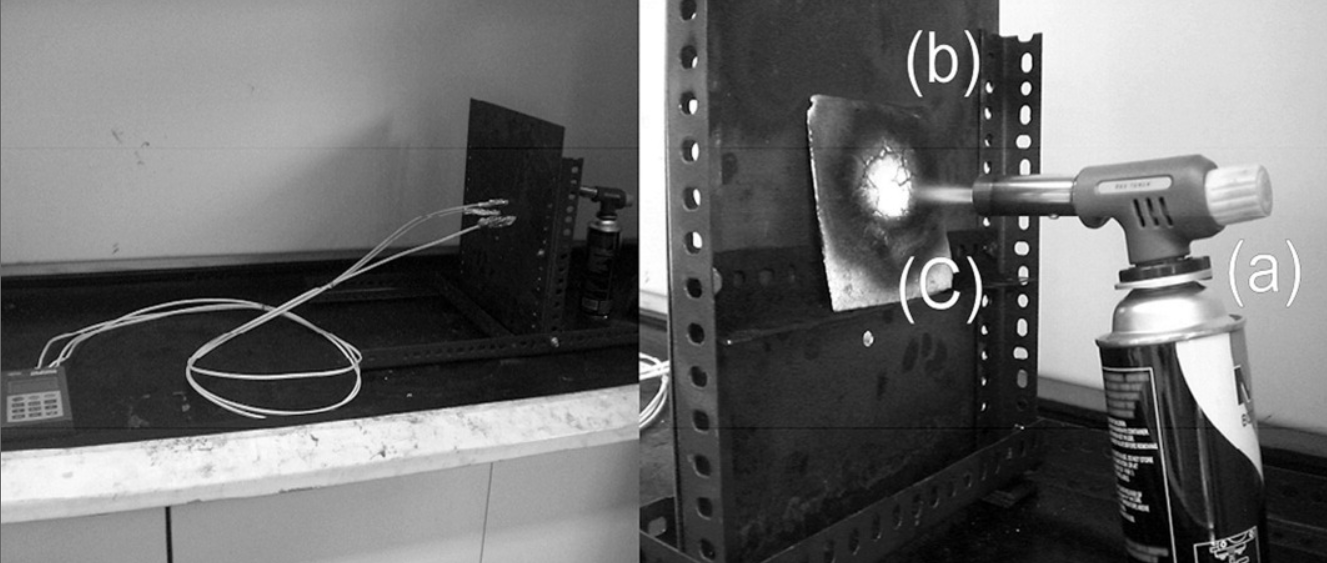

Graphite flakes, melamine, and boric acid were purchased from Sigma-Aldrich (M) Sdn. Bhd. (Malaysia). APP was provided by Clariant (Malaysia) Sdn. Bhd. Acetic acid, sulfuric acid, KMnO4, BPA, and ACR hardener H-2310 polyamide amine were purchased from Mc-Growth Chemical Sdn. Bhd. (Malaysia). The structural steel A36M was supplied by TSA Industries (Ipoh) Sdn. Bhd. Malaysia.EG was prepared by the reaction of the graphite flakes with acetic acid, sulfuric acid, and potassium permanganate at a ratio of 1 : 2 : 0.5 : 0.07.11 All intumescent ingredients were mixed according to their respective weight percentages, as indicated in Table I. A shear mixer was used to mix the coating ingredients at 40 rpm for 30 min. A structural steel plate measuring 100 cm2 was used as the substrate. The coating was applied evenly onto the steel substrate with a brush. The coating thickness was ensured at 1.5 mm by measurement with a digital vernier caliper. Seven formulations were prepared, and the coated substrate was cured in an oven at 60°C for 1 h.

Impact & Benefits

Enhanced Fire Protection: The development of intumescent coatings, particularly those incorporating boric acid and melamine, significantly improves the heat insulation properties, leading to better fire protection for steel structures.

Reduction in Fire-Related Damage: Intumescent coatings expand upon exposure to fire, forming a thick protective char layer that insulates the substrate from extreme heat. This results in a substantial reduction in structural damage during fire incidents.

Life and Property Safety: By enhancing the fire resistance of buildings and critical infrastructure, these coatings can prevent loss of lives and property. The significant reduction in severe damage helps ensure the safety of occupants and valuable assets.

Environmental and Health Advantages: Unlike traditional halogen- and antimony-based fire retardants, which are toxic and environmentally unsafe, the use of boric acid and melamine in intumescent coatings offers a more eco-friendly alternative.

Technological Advancements: The research contributes to ongoing technological development in the field of fire retardants, showcasing the potential of novel formulations with boric acid and melamine.

Industry Applications: The improved formulations can be widely adopted in high-risk industries such as construction, oil and gas, and transportation, where fire safety is paramount.

Findings/Figures and Research Data

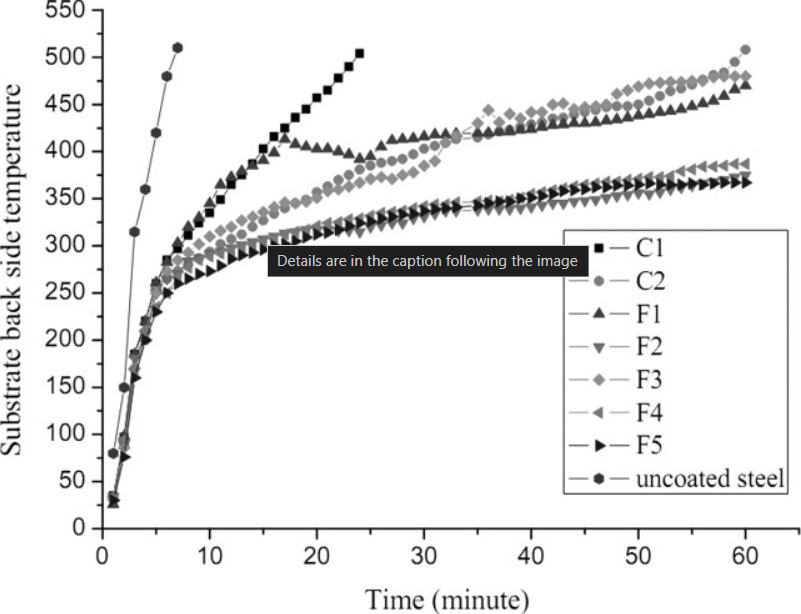

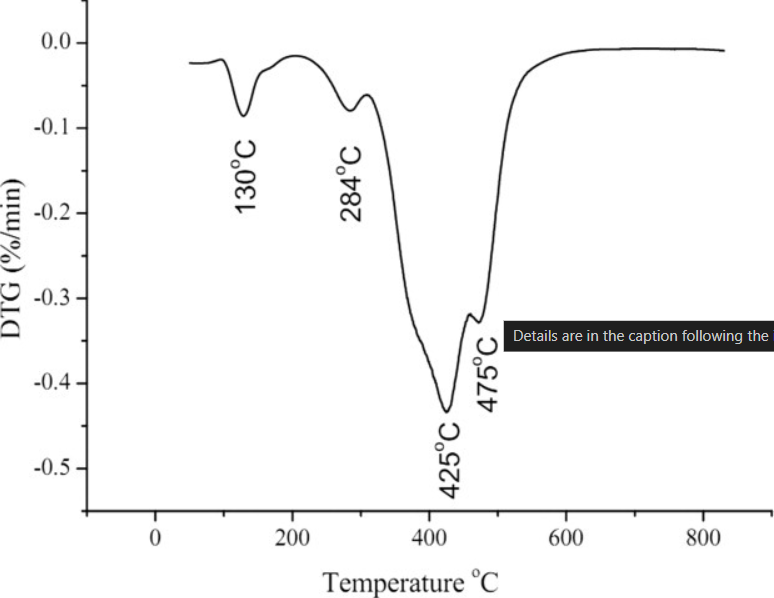

The decomposition of melamine remained at 284°C, whereas the decomposition of melamine phosphate started at 425°C, and the decomposition of boron phosphate occurred at 475°C. The shift in decomposition temperature of the F5 formulation was attributed to the increased boric acid weight percentage with respective to melamine. The results of TGA and DTGA showed similar thermal degradation behavior for the F4 and F5 formulations, as both formulations contained the same intumescent materials. However, the percentage weight loss was different, as the weight percentages of melamine and boric acid in the formulations were different. Increasing the weight percentage of boric acid with respect to melamine contributed to the increased residual weight. Among all of the formulations, F5 recorded the highest residual weight percentage of 29.67%, which was higher than those of C1, C2, F1, F2, and F4 by 42, 19, 31, 3.8, and 12%, respectively. This showed that the F5 coating enhanced the intumescent effect in terms of the residual weight percentage of char compared to other formulations.

Market Potential

Increasing Awareness of Fire Safety: The adoption of stringent building codes and fire safety standards necessitates the use of effective fire retardant materials, boosting demand.

Technological Advancements: Innovations leading to more environmentally friendly and less toxic fire retardants (as opposed to traditional halogen- and antimony-based retardants) are likely to drive market growth.

Safety in Critical Infrastructure: High-risk sectors such as offshore oil and gas facilities, chemical plants, and megabuildings are increasingly adopting intumescent coatings to prevent catastrophic failures during fire incidents.

Construction Industry: New constructions and retrofitting projects in both residential and commercial buildings represent a substantial market for intumescent coatings.

Industrial Applications: Compliance with Occupational Safety and Health Administration (OSHA) and other regulatory bodies mandates the use of fireproofing measures, expanding the market for intumescent coatings.