A review of powder additive manufacturing processes for metallic biomaterials

Author: Faiz Ahmad - March 2023

W.S.W. Harun, M.S.I.N. Kamariah, N. Muhamad, S.A.C. Ghani , Z. Mohamed

Abstract

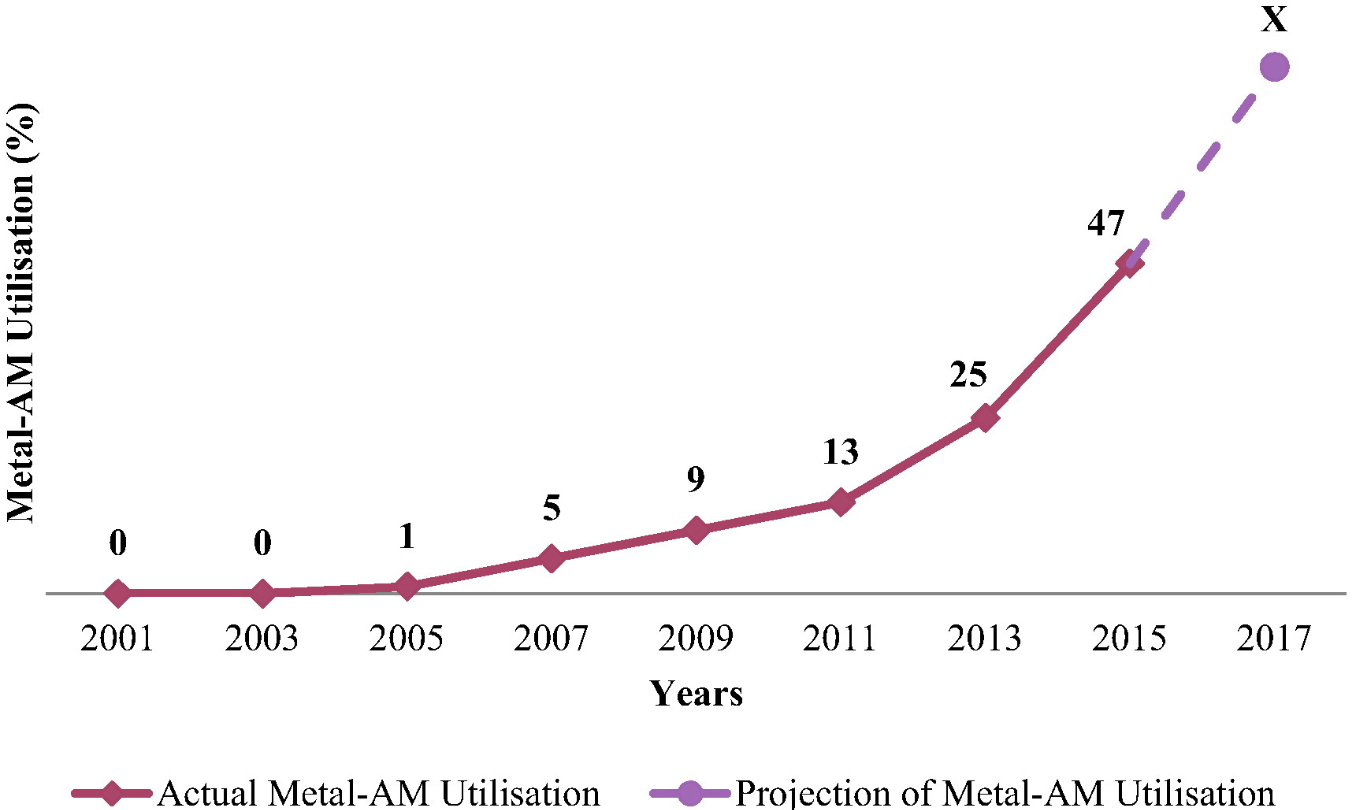

Metal additive manufacturing (metal-AM) has undergone a remarkable evolution over the past three decades. It was first used solely as an innovative resource of the prototype. Due to the technology maturity which allows combining various manufacturing processes for the production of a bespoke part that applied complex geometries, additive manufacturing (AM) technology has captured an increasing attention. For the past ten years, it has moved into the mainstream of the industrialised field such as biomedicine. The review covers the recent progress of metal-AM manufacturing technologies, main types of metallic biomaterials, and most common biomedical applications. The direction of the future potential of metal-AM in biomedical research and implementation are further discussed. Selective laser melting (SLM), selective laser sintering (SLS), electron beam melting (EBM), and laser engineered net shaping (LENS) are the most common metal-based additive manufacturing processes employed in the production of the biocompatible parts. The evolution and favourite trend of the metal-AM technologies are highlighted in this review. Additionally, the advancement of metallic biomaterials such as titanium and its alloys, cobalt-based alloys, 316L stainless steel, nickel-titanium, and other metallic biomaterials is also presented since it leads to the transpired of several new studies in the scope of metal-AM in the medical field. The rise of metal-AM in the biomedical industry has also been significant, especially in orthopaedics and dental. The metal-AM is predicted to continue to dominate and further benefit the biomedical industry development.

Methodology

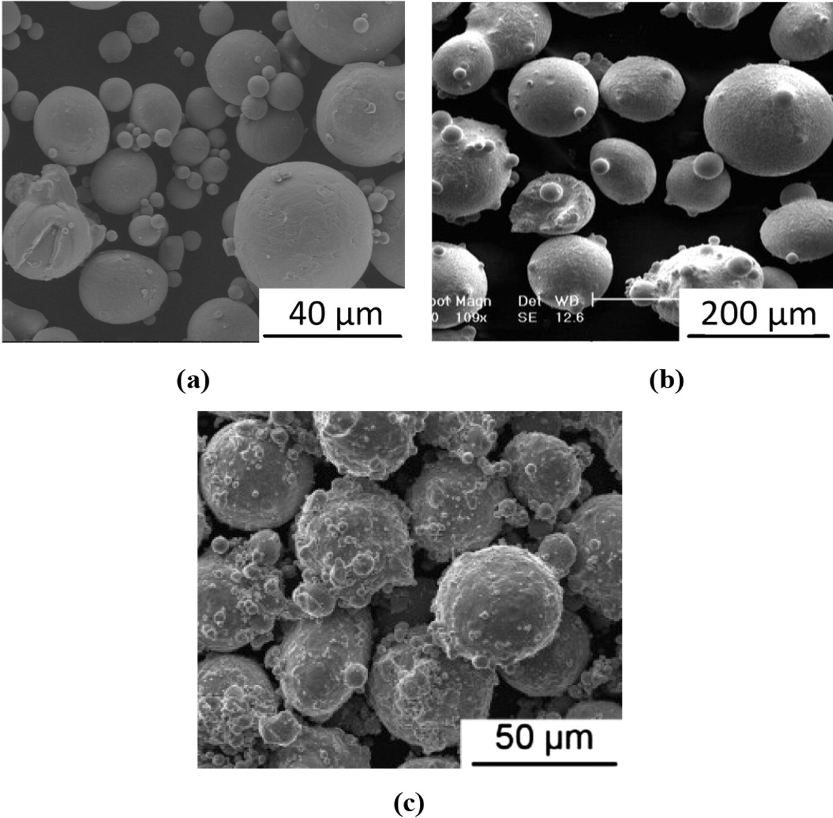

The AM techniques for biomaterials are divided into two main categories namely, acellular and cellular. Acellular entails processing of biomaterials without any living cells, whereas cellular involves the living cells together with biomaterials. Generally, the acellular AM technologies can be classified into seven techniques according to the American Society for Testing of Materials (ASTM) Standard namely, 1) binder jetting, 2) directed energy deposition, 3) material extrusion, 4) material jetting, 5) powder bed fusion, 6) sheet lamination, and 7) vat photopolymerisation [106]. The individual processes of AM are different depending on the material and machine technology applied. There are a few metal-AM processes for powder-based metallic feedstock system, which can be found in AM technologies of powder bed fusion and directed energy deposition. Powder bed fusion technique uses thermal energy either a laser or electron beam to fuse particle powder of material together at particular areas on a powder bed. This technique highlights the advantages including its ability to manufacture small complex parts but high dimensional accuracy, fabricate without necessary support, and a wide range of powders. Powder bed fusion has contributed as one of those from the first generation that commercialises the AM processes. There are a few types of powder bed fusion processes capable in processing biocompatible powder metal, namely selective laser melting (SLM), electron beam melting (EBM), and selective laser sintering (SLS).

Impact & Benefits

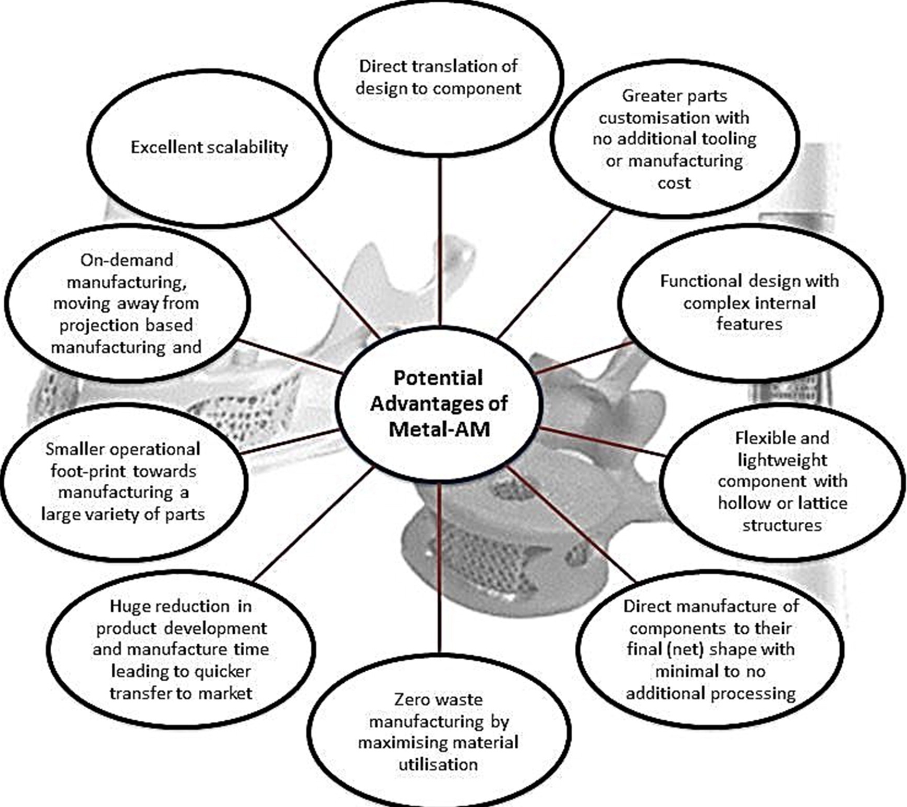

Revolutionizing Manufacturing Processes: AM technology shifts the paradigm from traditional subtractive and formative manufacturing methods to a layer-upon-layer material building process. This shift enables the creation of complex and bespoke parts that are difficult or impossible to achieve with conventional methods.

Customization and Personalization:AM allows for the production of patient-specific implants and devices, which are tailored to fit individual anatomical structures. This customization is crucial in fields such as orthopedics and dental care, where precise fit and function are essential.

Advancements in Biomedical Applications:The adoption of AM in biomedical applications has led to significant innovations in producing orthopaedic implants, dental devices, cardiovascular stents, tissue scaffolds, and other medical tools. These advancements have improved patient outcomes and expanded the possibilities of medical treatments.

Complex Geometries and Bespoke Designs: AM enables the creation of complex geometries and bespoke designs that are not possible with traditional manufacturing techniques. This capability is particularly beneficial in creating intricate medical implants and devices tailored to individual patient needs.

Cost and Time Efficiency: AM reduces production lead times and costs by streamlining the manufacturing process. It eliminates the need for extensive tooling and setup, allowing for faster production cycles and reduced material waste.

Environmental Sustainability:AM is a more sustainable manufacturing process, reducing material waste and energy consumption compared to traditional methods. This environmental benefit is increasingly important as industries strive to minimize their ecological footprint.

Findings/Figures and Research Data

The rise of metal-AM in the biomedical industry has excellently led the usage mainly in orthopaedics and dental implants. Metal-AM was first adopted to manufacture tailored implant or manufacturing incapability by other manufacturing techniques. Furthermore, tissue engineering is another multi-discipline area of application. In general, three-dimensional structures with pores provide support for the cell to attach, grow, and differentiate into functional tissue or organs. These architectures can be made using the metal-AM techniques with different micro- and macroporosity. The additional discussion is presented in the subsequent subsections.

Market Potential

Technological Maturity: Metal-AM techniques such as Selective Laser Melting (SLM), Electron Beam Melting (EBM), Direct Metal Laser Sintering (DMLS), and Laser Engineered Net Shaping (LENS) have matured, offering high accuracy, material diversity, and controlled mechanical properties.

Unique Capabilities: AM allows for the production of complex, bespoke parts that are not feasible with traditional manufacturing methods.

Biomedical Sector: Customization for patient-specific needs, such as anatomical bone defects and unique dental structures, is a significant advantage.

Material Compatibility: Biocompatible metals such as titanium, cobalt-based alloys, and stainless steel are commonly used in AM for medical applications due to their excellent mechanical properties and biocompatibility.

Cost Efficiency: AM offers cost savings by reducing lead times and material costs, which is particularly beneficial in the high-demand biomedical sector.