A review of biocompatible metal injection moulding process parameters for biomedical applications

Author: Faiz Ahmad - September 2017

M.F.F.A. Hamidi, W.S.W. Harun, M. Samykano, S.A.C. Ghani, Z. Ghazalli, F. Ahmad , A.B. Sulong

Abstract

Biocompatible metals have been revolutionizing the biomedical field, predominantly in human implant applications, where these metals widely used as a substitute to or as function restoration of degenerated tissues or organs. Powder metallurgy techniques, in specific the metal injection moulding (MIM) process, have been employed for the fabrication of controlled porous structures used for dental and orthopaedic surgical implants. The porous metal implant allows bony tissue ingrowth on the implant surface, thereby enhancing fixation and recovery. This paper elaborates a systematic classification of various biocompatible metals from the aspect of MIM process as used in medical industries. In this study, three biocompatible metals are reviewed-stainless steels, cobalt alloys, and titanium alloys. The applications of MIM technology in biomedicine focusing primarily on the MIM process setting parameters discussed thoroughly. This paper should be of value to investigators who are interested in state of the art of metal powder metallurgy, particularly the MIM technology for biocompatible metal implant design and development.

Methodology

The use of metallic materials for medical applications, especially implant devices can be traced back from the 19th century (metal industry revolt era, also known as Industrial Revolution Era). The progression of the metallic implants was instigated by the demands for better means to bone repair, especially for long bone internal fracture fixation [12]. Numerous types of metals have been tried and used in biomedicine according to the required specification of an implant. However, the most popular and accepted biocompatible metals at present for implants are from stainless steel, titanium and its alloys, and cobalt based alloys. Table 1 summarizes the types of metals used for different implant devices

Impact & Benefits

Functional Restoration: Biocompatible metal implants are extensively used to replace and restore the function of damaged tissues and organs, such as bones, joints, and heart valves. This restoration allows patients to regain mobility and functionality, thereby significantly enhancing their quality of life.

Mechanical Strength: Metals like stainless steel, titanium, and cobalt alloys offer superior mechanical properties, including high tensile strength, fracture toughness, and fatigue resistance. This ensures the implants can withstand the physical stresses of the human body over extended periods.

Improved BiocompatibilityAdvances in the selection and treatment of biocompatible metals have improved their ability to integrate with human tissues. This integration minimizes immune responses and enhances the stability and functionality of the implants.

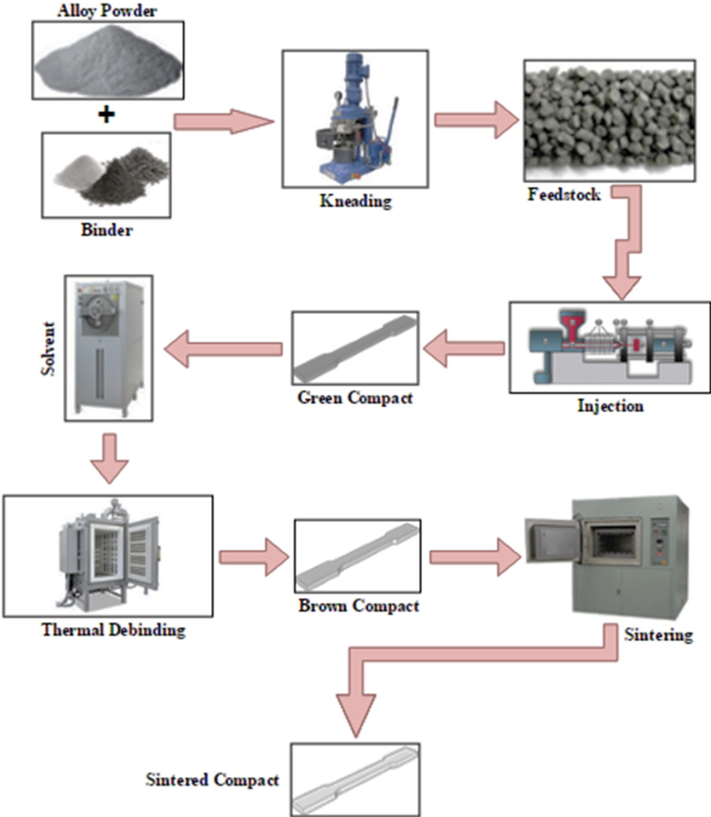

Advancements in Surgical TechniquesTechniques like Powder Metallurgy (PM) and Metal Injection Molding (MIM) allow for the production of highly precise and complex implant shapes. This precision facilitates better-fitting implants that are tailored to individual patient needs.

Economic and Mass Production BenefitsThe MIM technique, inspired by plastic injection molding, allows for the economical mass production of high-quality implants. This reduces costs for both manufacturers and patients.

Findings/Figures and Research Data

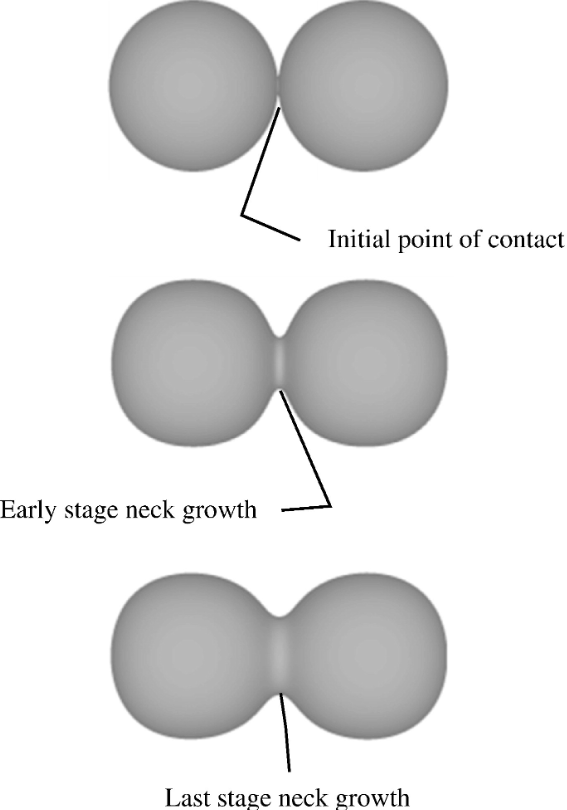

Among of the three biocompatible metals that discussed in this paper, the titanium and its alloys are the most favorable biocompatible metal preferred by the present researchers. These are due to the advantages of titanium alloys as it possesses excellent corrosion resistance, biocompatibility, and mechanical properties. Besides, titanium also exhibits low Young's modulus compared to stainless steel and cobalt based alloy (comparable to human bone). For future medical industries technology, titanium and its alloys seem to be the most preferred metal for a long-term bio-device component. MIM process parameters will nevertheless remain the same as there are no significant differences in the trend of the parameters used by investigators such as powder loading, binder materials, de-binding, and sintering parameters.

Market Potential

Aging Population: The global population is aging, and with age comes an increased incidence of conditions like osteoporosis, arthritis, and other degenerative diseases. This demographic shift drives the demand for medical implants such as artificial joints, dental implants, and heart valves.>

Advancements in Medical Technology: Continued advancements in medical technology, including more sophisticated diagnostic tools and surgical techniques, are increasing the range and efficacy of implantable devices. The development of biocompatible metals with improved properties enhances the functionality and longevity of these implants.

Increase in Chronic Diseases: There is a rising prevalence of chronic diseases such as cardiovascular diseases and diabetes, which often require surgical interventions involving implants. For example, the increasing number of cardiovascular disease cases boosts the demand for stents and artificial heart valves.Increase in Chronic Diseases

Growing Acceptance and Usage of Implants: With successful historical use and continuous improvements, there is growing acceptance of metal implants within the medical community. The acceptance has broadened from just metals to advanced materials like titanium alloys and cobalt-based alloys, known for their exceptional mechanical properties and biocompatibility.

Innovations in Manufacturing Techniques: Techniques like Powder Metallurgy (PM) and Metal Injection Molding (MIM) are revolutionizing the production of implants. MIM, in particular, offers cost-effective mass production, near-net shaping for complex designs, and high-density components with excellent dimensional accuracy. These innovations contribute to reduced manufacturing costs and increased availability of high-quality implants.