Effects of solid loading and cooling rate on the mechanical properties and corrosion behavior of powder injection molded 316 L stainless steel

Author: Faiz Ahmad - February 2016

Muhammad Rafi Raza, Faiz Ahmad, Norhamidi Muhamad, Abu Bakar Sulong, M.A. Omar, Majid Niaz Akhtar , Muhammad Aslam

Abstract

Solid loading and post-sintered cooling rates are two effective parameters used to control the mechanical properties of powder-injection molded parts. In the case of 316 L stainless steel (SS), these parameters also influence mechanical properties and corrosion resistance. In this study, four formulations with powder loading above and below the critical powder loading were prepared and sintered at 1325 °C in vacuum with cooling rates varying from 3 °C/min to 10 °C/min. Solid loadings above the critical loading caused reductions in final properties (i.e. mechanical properties and corrosion resistance) because of increased porosity. The high cooling rate of 10 °C/min improved the mechanical properties due to the formation of large number of grains and corrosion resistance due to formation of chromium oxide layer at the surface of PIM 316 L SS. Solid loading of 65 vol.%, sintered at 1325 °C with a cooling rate of 10 °C/min showed improvements in terms of mechanical properties and corrosion resistance compared with conventional 316 L SS. Such improvements were considered due to reduced grain sizes and formation of a chromium oxide layer on the sample surface. This study identifies the solid loading (65 vol.%) below the critical powder loading and a high post-sintered cooling rate, i.e., 10 °C/min, are suitable to achieve optimum mechanical properties and corrosion resistance in 316 L SS. The developed material may be recommended for biomedical applications.

Methodology

The critical solid loading was measured by using torque rheometry. During the experiment, oleic acid was used as a binder. At critical powder loading, the metal particles are tightly packed without external pressure, and the voids between particles are completely filled with the binder. The critical solid loading can help determine the optimum solid loading. After determination of the critical powder loading (i.e. 66 vol%), four formulations of feedstock, i.e., F1, F2, F3, and F4, above and below the critical solid loading were prepared with solid loadings of 60 vol.%, 65 vol.%, 67 vol.%, and 69 vol.%, respectively. Multi component binder system was used and consists of Paraffin Wax (PW) 75 vol.%, Polypropylene (PP) 20 vol.% and Stearic Acid (SA) 5 vol.%. SS powder and wax-based binder were mixed using a Z-blade mixer at 180 = 5 °C for 90 min at 60 rpm. After mixing, the paste was dried and converted into granules. The test specimens were molded using a 100 KSA vertical injection molding machine according to MPIF standard 50. All formulations were molded at 180 °C. The molding dwell time was varied from 18 to 30 s depending on the solid loading. No physical defects were observed on the surface of the test samples.

Impact & Benefits

Advancement in PIM Technology: The article deepens the understanding of the PIM process by investigating critical parameters like particle size distribution, solid loading, and sintering conditions. This knowledge can lead to more efficient and precise manufacturing processes.

Improved Implant Performance: The research addresses the critical issue of implant failure due to corrosion. The findings suggest that optimized PIM processes can produce implants with significantly improved corrosion resistance, which can extend the lifespan and reliability of medical devices.

Standardization and Benchmarking: By characterizing the sintered samples according to ASTM standards, the study ensures that the results are reliable and can be compared with other research, facilitating broader acceptance and implementation of the findings in the industry.

Economic Efficiency: PIM is known for its cost efficiency in producing complex parts. The improvements in the process can make it even more economically attractive, reducing manufacturing costs while enhancing product quality.

Mechanical Properties: The study shows that with optimal solid loading and post-sintering cooling rates, the mechanical properties of 316L SS can be significantly improved. This includes a tensile strength of 501 MPa and a hardness of 204 Hv.

Broader Applications While the study focuses on medical implants, the insights gained can be applied to other industries where 316L SS is used, such as aerospace, automotive, and electronics, broadening the scope of the benefits.

Findings/Figures and Research Data

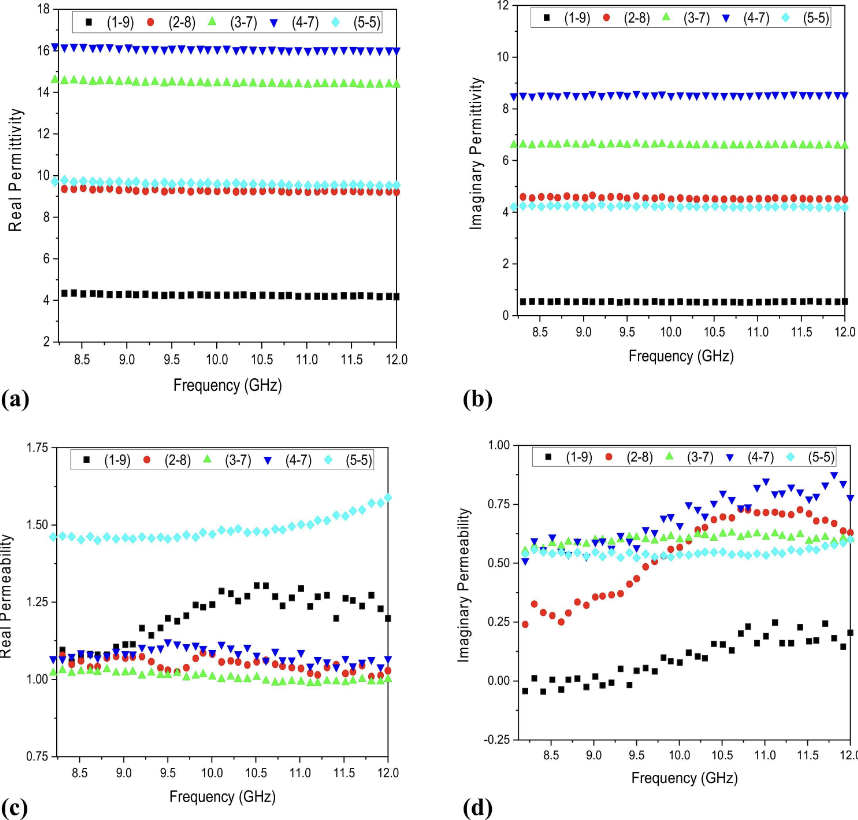

Based on the results shown in Fig. 13, it is concluded that the corrosion rate decreases by increasing the solid loading below the critical solid loading, i.e., 66 vol.%. This result was attributed to the decrease of pinhole porosity of the sintered samples. High-vacuum sintering and higher post sintering cooling rate used in this study minimize Cr evaporation during sintering and enhance the formation of Cr3O2 passive layer during cooling respectively. This approach resulted in the retention of Cr on the surface of the test sample in the form of a passive oxide layer (Cr3O2), which improves corrosion resistance. Higher post-sintering cooling rate provided less diffusion time to the Cr within the matrix and inhibit carbide formation [25], [26], [27], [28]. The results achieved are better than those previously reported for 316 L SS tested in a chloride environment [29]. Detailed atomic absorption spectra are given in Table 3. A large number of metal ions were released from sintered samples with solid loadings above the critical loading and low post-sintered cooling rates.ss

Market Potential

Versatility and Cost Efficiency: PIM technology is recognized for its ability to produce complex parts with high dimensional accuracy at relatively low costs. This makes it an attractive option for various industries including automotive, aerospace, electronics, and medical devices.

Medical Applications:316L SS is widely used in medical implants due to its mechanical properties and corrosion resistance. The material'ss use in implants addresses the significant issue of metal ion release, which can cause allergic reactions and carcinogenic effects. Research focused on improving these properties through PIM can further bolster its application in the medical field.

Growing Healthcare Industry: The global healthcare industry is expanding, with an increasing demand for advanced medical implants. Innovations that improve the durability and safety of implants are highly valuable.

Improvement in Manufacturing Processes: The PIM process's ability to produce high-density, corrosion-resistant 316L SS components can significantly reduce manufacturing costs and enhance the scalability of production.