The role of multi-wall carbon nanotubes in char strength of epoxy based intumescent fire retardant coating

Author: Faiz Ahmad - March 2017

Sami Ullah, A.M. Shariff, M. Rafi Raza, Patrick J. Masset

Abstract

Fire resistance of coatings mostly depends on the formation of char. In this work Multi-wall carbon nanotubes (MWCNTs) were used to improve fire retardant and char properties of the intumescent coating. Different coating formulations were prepared and their heat shielding performance was tested at 950 °C according to ASTM E-119. Char expansion was studied using fire furnace test. Field emission scanning electron microscope was used for char morphology. By means of X-ray Diffraction and Fourier transform infrared spectroscopy the presence of carbon, borophosphate; boron oxide and sassolite in the char was identified. Thermogravimetric analysis results showed that 0.5 wt%MWCNTs enhanced the residual weight of char up to 29.35 wt%. X-ray photoelectron spectroscopy (XPS) confirmed that 0.5 wt% MWCNTs enhanced the carbon content up to 51.90 wt%, lowering oxygen content to approximately 25 wt% in the char that improved the fire resistance performance of the coating. Pyrolysis analysis confirmed that 0.5 wt% MWCNTs formulation released less gaseous products and reduced the decomposition of gaseous products. An accelerated weathering test ASTM D 6695-03 also revealed that 0.5 wt% of MWCNTs sustained its reliability up to 90 days in accelerated.

Methodology

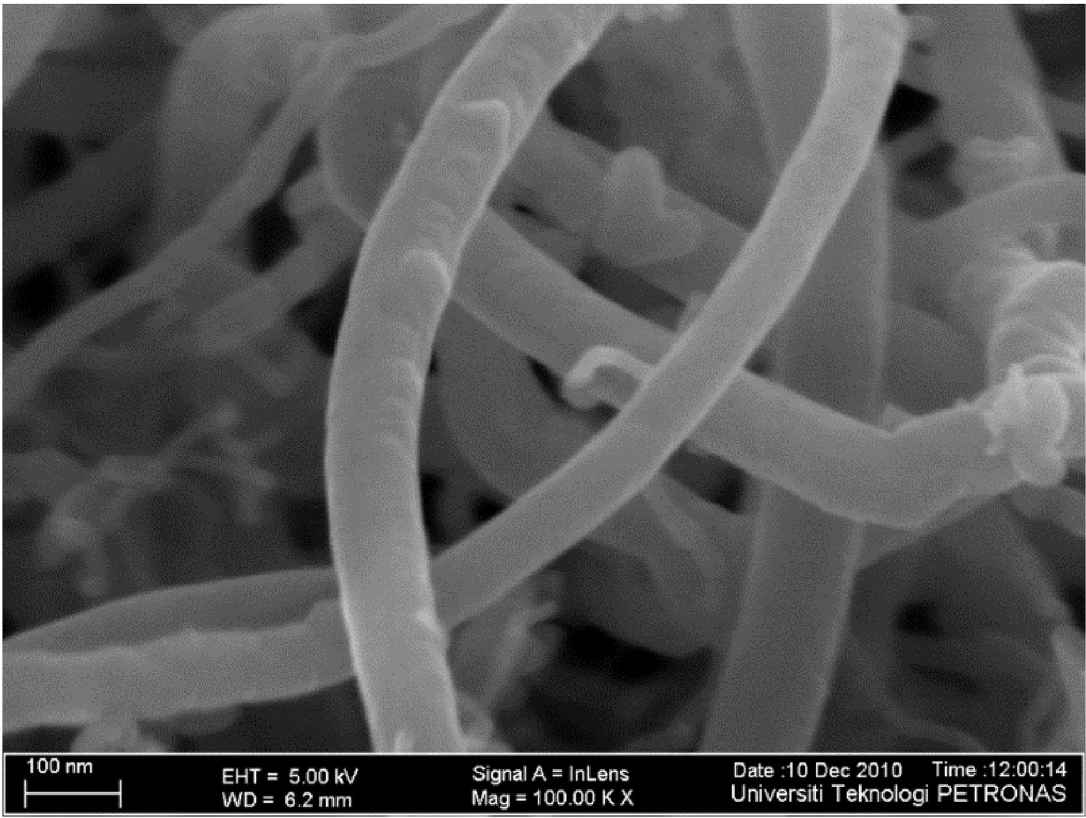

Flake graphite, melamine (Mel) and boric acid (B.A) were purchased from Sigma-Aldrich (M) Sdn Bhd. Malaysia. Ammonium polyphosphate (APP) was provided by Clariant (Malaysia) Sdn Bhd. Acetic acid, sulphuric acid, KMnO4, binder system bisphenol An epoxy resin BE-188 (BPA) and ACR Hardener H-2310 polyamide amine and Multi-Wall Carbon Nanotubes (MWCNTs) were purchased from Sigma-Aldrich chemical Sdn Bhd. Malaysia. Structural steel A36 M was supplied by TSA industries (Ipoh) Sdn. Bhd. Malaysia. MWCNTs were produced on cathode deposit, carbon content >99%. The dimensions of MWCNTs were: O.D. x L 7-15 nm x 0.5-10 um, its melting point is 3652-3697 °C(lit.) and density ~2.1 g/mL at 25 °C(lit.) as per stated by the supplier. The field emission scanning electron microscope (FESEM) micrograph of MWCNTs used in this work is shown in Fig. 1.

Impact & Benefits

Improved Fire Resistance and Thermal Stability: MWCNTs promote the formation of a stable, protective char layer during thermal degradation, significantly improving fire resistance.

Structural and Chemical Improvements: MWCNTs help create a more uniform char structure, reducing pathways and gaps that allow heat transfer, thus offering better thermal protection.

Physical Properties Enhancement: The presence of MWCNTs increases the density of the char, making it more effective in insulating the underlying material.

Chemical Composition Benefits: The addition of MWCNTs results in fewer gaseous products being released during decomposition, improving safety and environmental impact..

Reduced Emissions:The incorporation of fillers such as metal oxides (e.g., Al2O3, TiO2) and hexagonal boron nitride improves the overall fire resistance characteristics of coatings. These enhancements include better char formation, reduced flammability, and improved adhesion to substrates.

Findings/Figures and Research Data

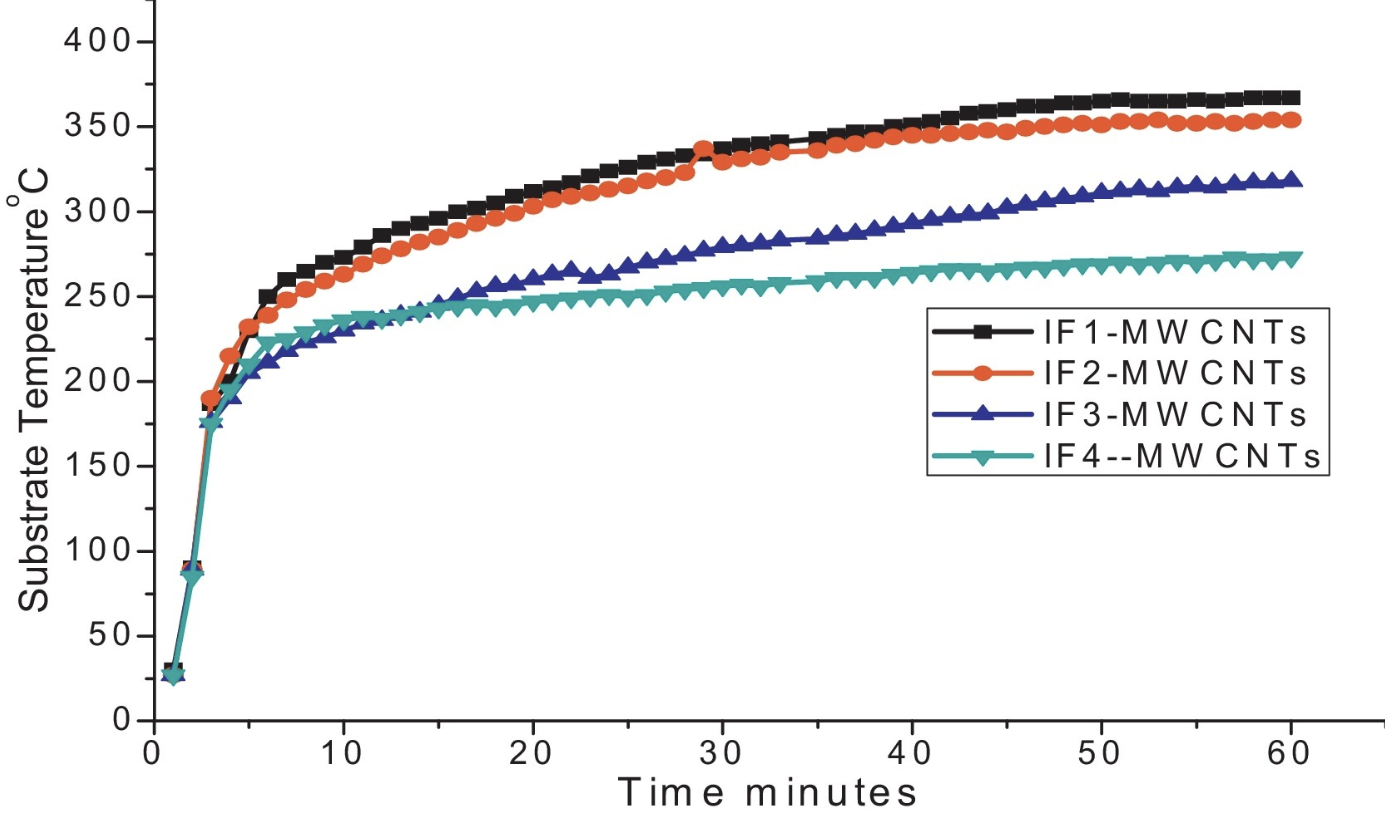

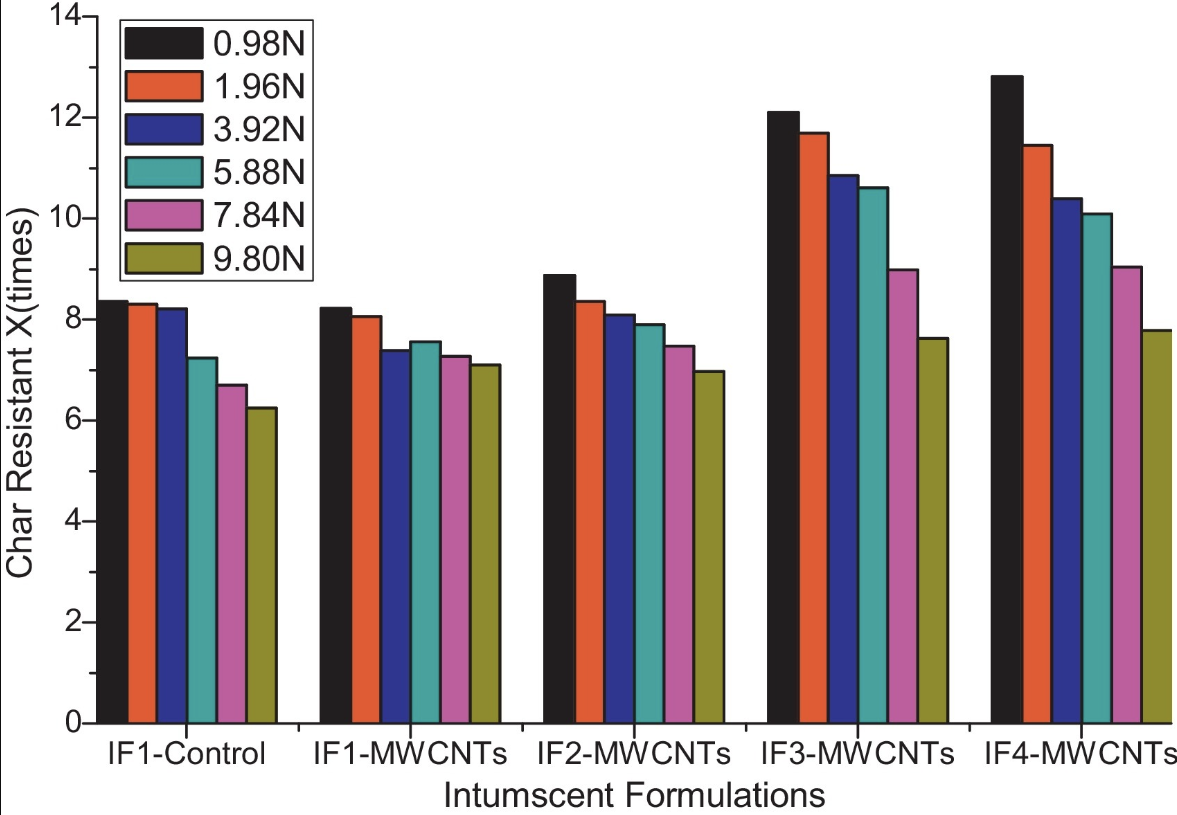

According to the data in Fig. 2, MWCNTs significantly reduce the substrate temperature, with IF4-MWCNTs showing the lowest temperatures of 256 °C at 30 minutes and 273 °C at 60 minutes, compared to IF1-Control. Specifically, the substrate temperatures for IF2-MWCNTs and IF3-MWCNTs were also lower than the control, showing a decrease of 13 °C, 49 °C, and 94 °C with 0.3%, 0.4%, and 0.5% MWCNTs, respectively, after 30 minutes. After 60 minutes, IF4-MWCNTs had the lowest temperature, being 81 °C and 45 °C lower than IF2-MWCNTs and IF3-MWCNTs, respectively. Additionally, as shown in Fig. 3, MWCNTs reinforcement enhances char strength, with a higher mass percentage of MWCNTs leading to a greater decrease in char expansion, indicating stronger char. IF4-MWCNTs demonstrated substantial improvements in char resistance, with increases of 53%, 38%, 26%, 37%, 34%, and 22% compared to IF1-Control under loads ranging from 0.98 N to 9.80 N. This enhanced char expansion and structure significantly contribute to the fire-resistant properties of the coatings..

Market Potential

MWCNTs reinforce the char layer formed during thermal degradation, leading to increased thermal stability and reduced combustibility. This is achieved through improved char density, reduced substrate temperatures, and enhanced char strength, which are critical factors in fire protection. MWCNTs are cost-effective, commercially viable, and can be produced on a large scale. Their unique properties, such as high thermal conductivity, mechanical strength, and low density, make them superior to traditional materials like clay and carbon nanofibers. The research indicates that even small concentrations of MWCNTs (as low as 1%) can effectively enhance flame retardancy and insulation, making them ideal for use in various applications, including structural materials, polymers, ceramics, and metallic matrices. The ability of MWCNTs to improve the physical and non-flammable properties of nanocomposites positions them as a promising solution for developing high-performance, fire-resistant coatings, opening new opportunities in industries requiring advanced thermal control and protection solutions.